Welcome To CHUANGRONG

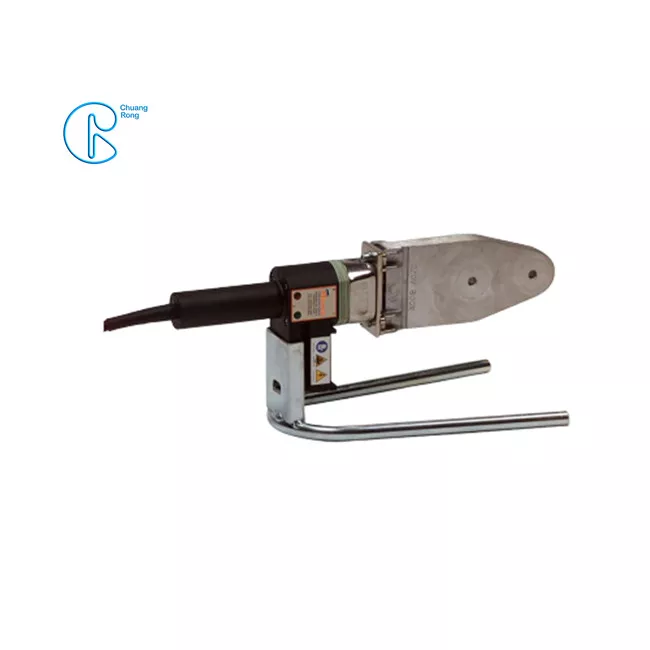

Poly Pipe Socket Fusion Machine Handle Small PPR Welding Machine

Basic Information

| Model NO.: | R 63mm | Max Diameter: | 63mm |

|---|---|---|---|

| Absorbed Power: | 800W | Dimension: | 175*50*360mm |

| Working Temperature: | Tfe:260oc(+/-10oc);Te:180oc~290oc | Transport Package: | Plastic Box |

Product Description

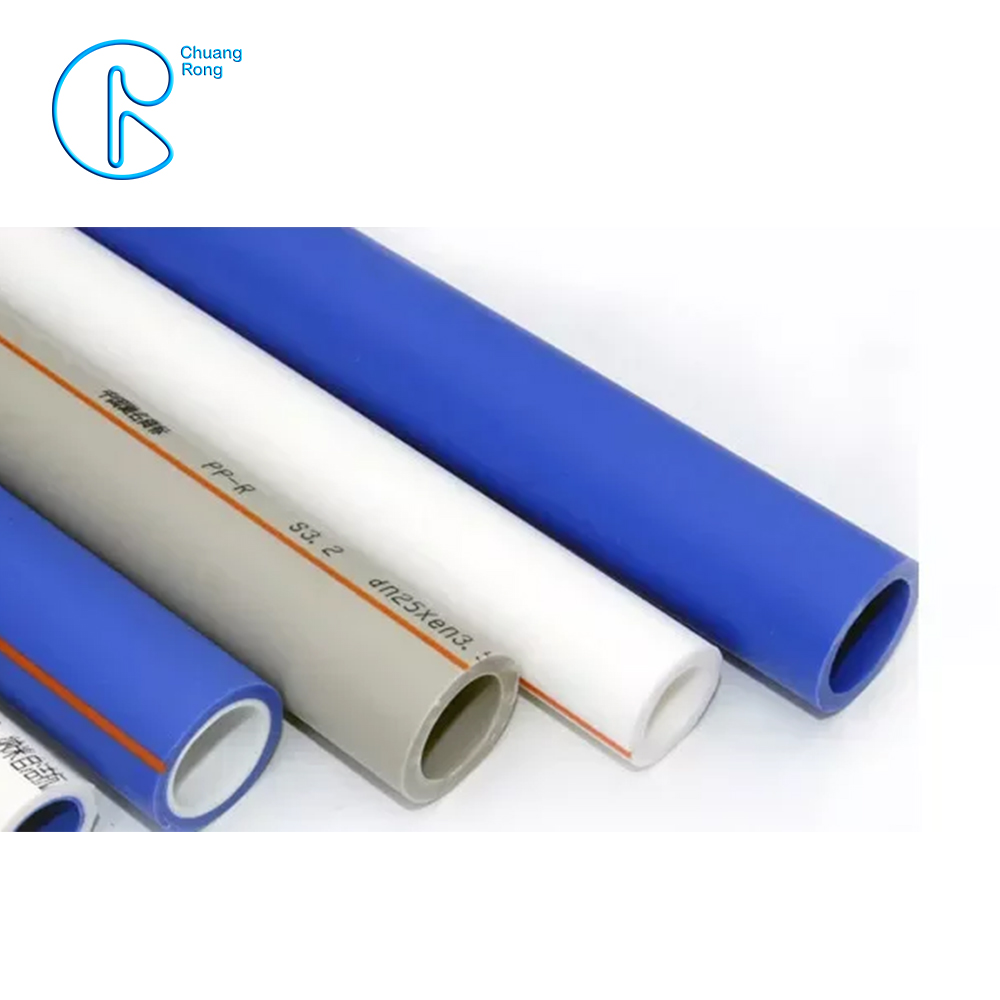

Manual soket welders for jointing pipe and fittings, in compliance with the standars in force. They feature an aluminum heating plate and a practial, heating-insulated plastic handle. They can weld HDPE, PP, PPR, PVDF pipes and fititngs, and they’re characteerized by different shaps and working ranges, suitable for different applications. They’re available with an adjustable eletronic themmoregulator(TE), or with a fixed electronic thermostat(TFE).

Details of PPR welding machine

| Material | PE, PP, PP-R, PVDF | ||

| Max Diameter | 63mm | ||

| Absorbed Power | 800W | ||

| Weight | 1.82 kg | ||

| Dimension | 175*50*360mm | ||

| Working temperature | TFE:260ºC(+/-10ºC);TE:180ºC~290ºC | ||

| Ambient temperature | -5~40ºC | ||

| Power supply | TE:230V-Single phase 50/60Hz;TFE:110~230V Single phase 50/60 Hz | ||

OPERATING INSTRUCTIONS

4.1. Check that the mains voltage is the same as

the voltage stated on the socket fusion welding

machine plate.

4.2. DEVICES FOR USING THE SOCKET FUSION

WELDING MACHINE

a b

a) Fork.Suitable for welding on the floor.

b) Bench bracket. For bench work.

c) Platform. An alternative to the fork.

4.3. Fit the socket fusion welding machine to the

chosen device.

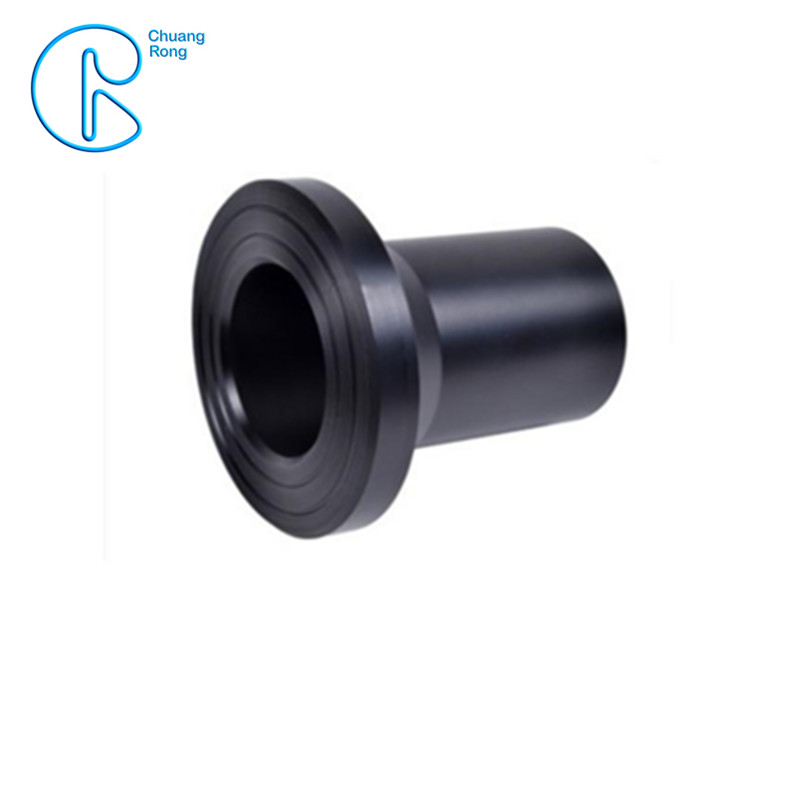

4.4. Fit the M/F bushes according to requirements.

N.B.: The surface of the bush in contact with the welding machine must be kept clean at all times.

4.5. Clamp the bushes tightly to the Socket fusion welding machine (using a wrench) to obtain the necessary heat exchange for the temperature

required for the bushes

A: Hexagonal wrench

B: Pin unit for bushes

4.6. Plug into the mains

4.6.1. TE MODELS

|

|

Show LO v after power on。After 10-20 minutes, the heating plate starts to show the temperature, reaching the set temperature and then stabilizingPress the set keyto enter the tempering mode and set the temperature according to the + -.Press - to switch mode. |

4.7. 10 - 15 minutes after the socket fusion welding machine is switched on ( or in any case when it has reached operating temperature).

All plastic welding machines supplied are set to a bush temperature of about 260° C.

Check that the edge of the bush is as specified by the manufacturer of the pipe to be welded.Use a

digital thermometer

Precision temperature adjustment between 180° C

and 290° C is possible. Use a digital thermometer

to measure even slight variations

Packing

Other

Send your message to us:

Products categories

-

Phone

-

E-mail

-

Whatsapp

-

Skype

-

Top