Welcome To CHUANGRONG

HDPE Electrofusion Branch Saddle PN16 SDR11 For Gas or Water Transportation

Detail Information

CHUANGRONG and its affiliated companies specialize in the R&D, production, sale and installation of new-type plastic pipes and fittings. It owned five factories, one of the largest manufacturer and supplier of plastic pipes and fittings in China. Furthermore, the company owns more 100 sets pipe production lines that are advanced at domestic and abroad,200 sets of fitting production equipment. The production capacity reaches more than 100 thousand tons. Its main contain 6 systems of water, gas, dredging, mining, irrigation and electricity, more than 20 series and more than 7000 specifications.

CHUANGRONG can provide high quality HDPE Electrofusion Fittings for Water,Gas and Oil DN20-1200mm, SDR17, SDR11, SDR9 with bar code at competitive price.

HDPE Electrofusion Branch Saddle PN16 SDR11 For Gas or Water Transportation

|

Fittings Type |

Specification |

Diameter(mm) |

Pressure |

|

HDPE Electrofusion Fittings |

EF Coupler |

DN20-1400mm |

SDR17, SDR11 SDR9(50-400MM) |

|

EF Reducer |

DN20-1200mm |

SDR17, SDR11 SDR9(50-400MM) |

|

|

EF 45 deg elbow |

DN50-1000mm |

SDR17, SDR11 SDR9(50-400MM) |

|

|

EF 90 deg elbow |

DN25-1000mm |

SDR17, SDR11 SDR9(50-400MM) |

|

|

EF Tee |

DN20-800mm |

SDR17, SDR11 SDR9(50-400MM) |

|

|

EF Reducing Tee |

DN20-800mm |

SDR17, SDR11 SDR9(50-400MM) |

|

|

EF End Cap |

DN32-400mm |

SDR17, SDR11 SDR9(50-400MM) |

|

|

EF Stub End |

DN50-1000mm |

SDR17, SDR11 SDR9(50-400MM) |

|

|

EF Branch Saddle |

DN63-1600mm |

SDR17, SDR11 |

|

|

EF Tapping Saddle |

DN63-400mm |

SDR17, SDR11 |

|

|

EF Repair Saddle |

DN90-315mm |

SDR17, SDR11 |

Welcome to visit our factory or conduct a third-party audit.

Welcome to contact us for products details and professional service.

Please send email to: chuangrong@cdchuangrong.com

Product Description

Electrofusion HDPE Fittings Branch Saddle for Gas supply PN16 SDR11 PE100

1. Electrofusion HDPE fittings are welded by electrofusion machine to connect HDPE pipes together.

2. After electrofusion welding machine plug in electricity and turn on, The copper wire buried inserted in electric fuse.

3. HDPE fittings are heated and make HDPE melt, Which joint HDPE pipe and fittings well.

Thoughtful Service

1)CHUANGRONG, as China’s “GF”, we fully understand the needs of customers and provide customers with the most cost-effective solutions — one-stop product portfolio of HDPE pipe systems (HDPE pipes, fittings, welding machines and tools. Also for customers Provide high value-added services, 24 hours to answer customer questions.

2) Our ultimate goal is to add value to our customers through professional, efficient and cost-effective solutions.

3) Tailored solutions for customers. Combine our expertise in developing and producing pipelines systems, and deep industries and market knowledge, based on long-term experience to provide customers with cost-effective solutions.

| Application: | Gas,Water,Oil Etc | Product Name: | Electrofusion HDPE Fittings Branch Saddle For Gas Supply PN16 SDR11 PE100 |

|---|---|---|---|

| Specification: | 63*32mm~315*90mm PE100 PN16 SDR11 | Standard: | EN 12201-3:2011,EN 1555-3:2010 |

| Port: | China Main Port | Material: | PE100 Virgin Raw Material |

Certifications

Welcome to contact us for products details and professional service.

Please send email to: chuangrong@cdchuangrong.com or Tel: + 86-28-84319855

|

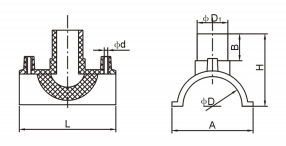

specifications φD×D1 |

L mm |

A mm |

B mm |

H mm |

d mm |

|

63×32 |

110 |

100 |

79 |

124 |

4.7 |

|

90×63 |

145 |

160 |

80 |

145 |

4.7 |

|

110×32 |

145 |

160 |

80 |

145 |

4.7 |

|

110×63 |

145 |

160 |

80 |

145 |

4.7 |

|

160×63 |

190 |

238 |

100 |

185 |

4.7 |

|

163×90 |

190 |

238 |

100 |

185 |

4.7 |

|

200×63 |

190 |

250 |

110 |

185 |

4.7 |

|

200×90 |

190 |

250 |

115 |

190 |

4.7 |

|

225×32 |

190 |

248 |

66 |

145 |

4.7 |

|

225×63 |

190 |

250 |

108 |

187 |

4.7 |

|

250×63 |

190 |

300 |

115 |

195 |

4.7 |

|

250×90 |

190 |

300 |

115 |

195 |

4.7 |

|

315×63 |

190 |

300 |

115 |

195 |

4.7 |

|

315×90 |

190 |

300 |

115 |

190 |

4.7 |

1. Municipal water supply, gas supply and agriculture etc.

2. Commercial & Residential water supply

3. Industrial liquids transportation

4. Sewage treatment

5. Food and chemical industry

6. Replacement of cement pipes and steel pipes

7. Argillaceous silt, mud transportation

8. Garden green pipe networks

| Test item | Standard | Conditions | Results | Unit |

| 1.Melt Flow Index | ISO1133 | 190°C & 5.0Kg 0.2-0.7 | 0.49 | g/10min |

| 2.Density | ISO1183 | @23°C ≥0.95 | 0.960 | g/cm3 |

| 3.Oxidation Induction Time | ISO11357 | 210°C >20 | 39 | Min |

| 4. Hydrostatic Pressure Test | ISO1167 | 80°C 165h, 5.4Mpa | Passed | |

| 5 Size Check | ISO3126 | 23°C | Passed | |

| 6 Appearance | Clean& Smooth | 23°C | Passed |

- The results according to test 1-3 are taken form the PE raw material supplier’s report.

- The results according to test 4-6 are taken from the internal test results of fittings sampled from thesame batch as delivered fittings.

- Marking according EN 12201 – 3 and EN 1555 – 3.

- The pass/fail criteria are based on the requirements of the UNI EN 12201 and UNI EN 1555 standards.

We can supply ISO9001-2015,WRAS, BV ,SGS, CE etc certification. All kinds of products are regularly conducted pressure-tight blasting test,longitudinal shrinkage rate test, quick stress crack resistance test, tensile test and melt index test, so as to ensure the quality of products totally reach the relevant standards from raw materials to finished products.

Send your message to us:

Products categories

-

Phone

-

E-mail

-

Whatsapp

-

Skype

-

Top