Welcome To CHUANGRONG

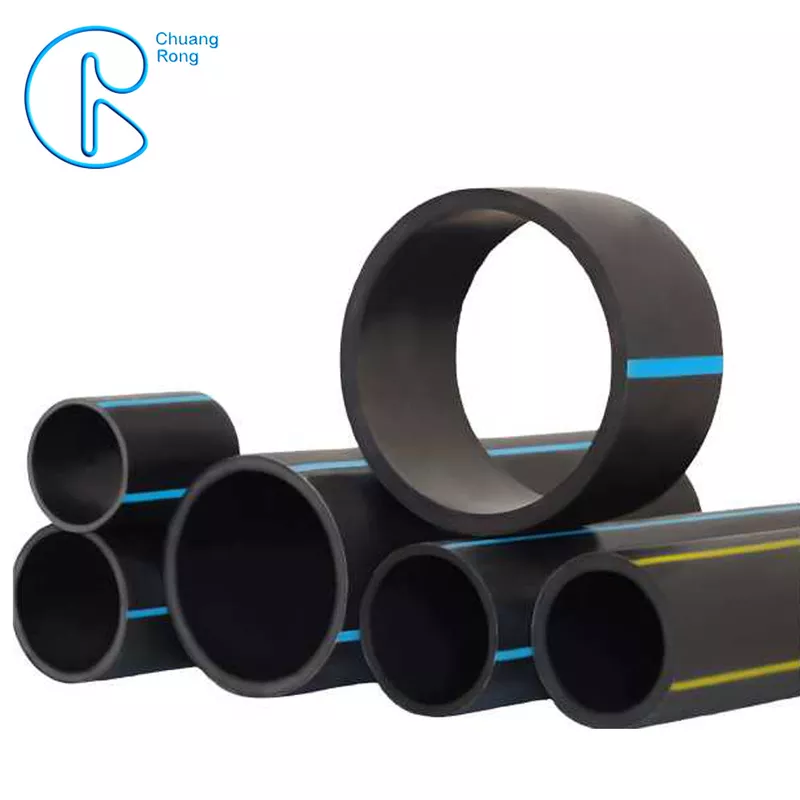

54mm 63mm 75mm Double Protection Pe UPP Pipe for Fuel Petrol Station

Basic Information

CHUANGRONG and its affiliated companies specialize in the R&D, production, sale and installation of new-type plastic pipes and fittings. It owned five factories, one of the largest manufacturer and supplier of plastic pipes and fittings in China. Furthermore, the company owns more 100 sets pipe production lines that are advanced at domestic and abroad,200 sets of fitting production equipment. The production capacity reaches more than 100 thousand tons. Its main contain 6 systems of water, gas, dredging, mining, irrigation and electricity, more than 20 series and more than 7000 specifications.

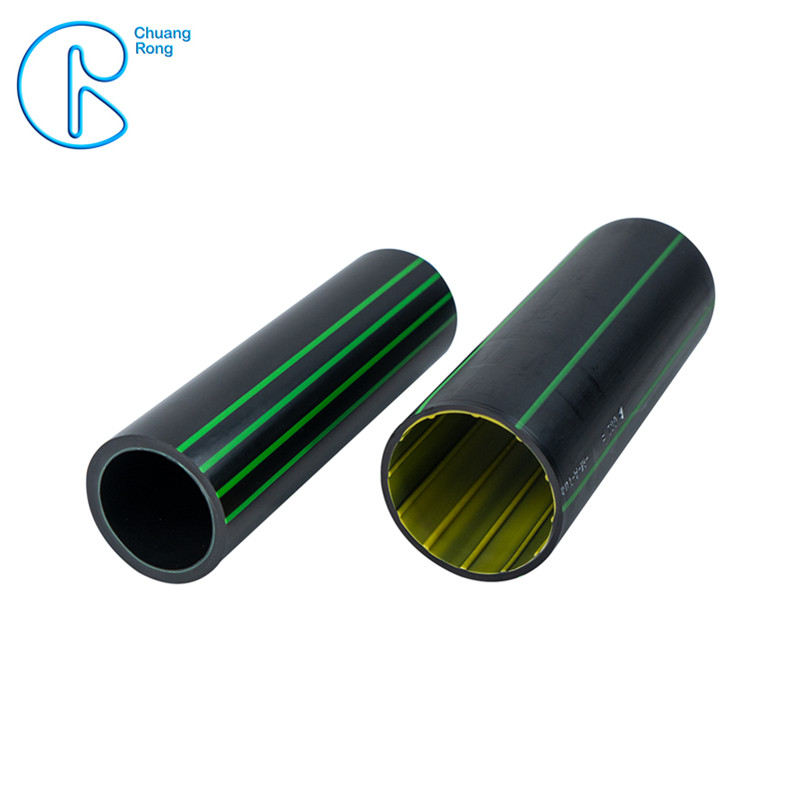

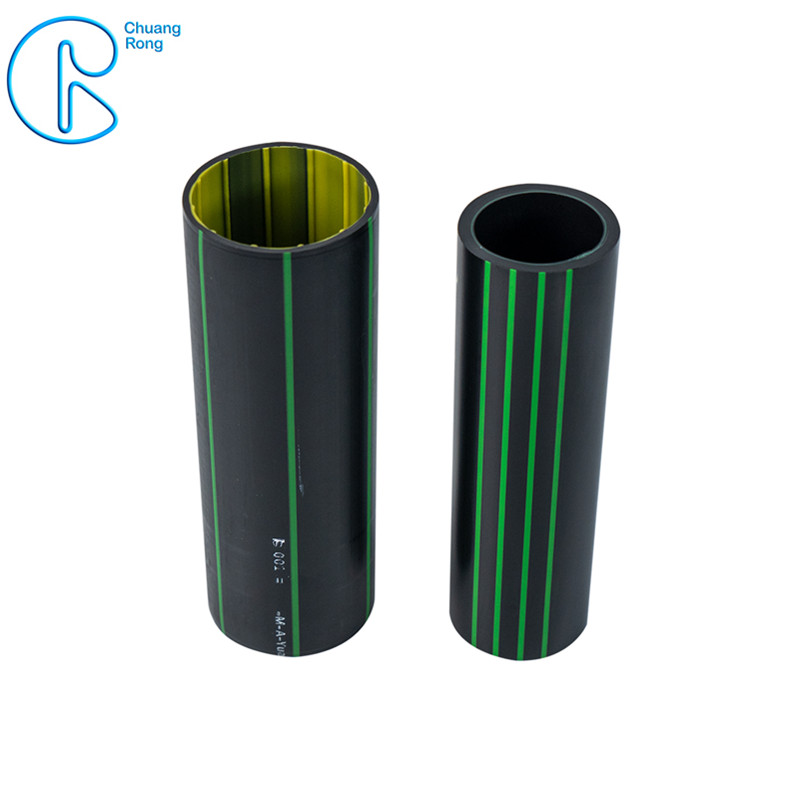

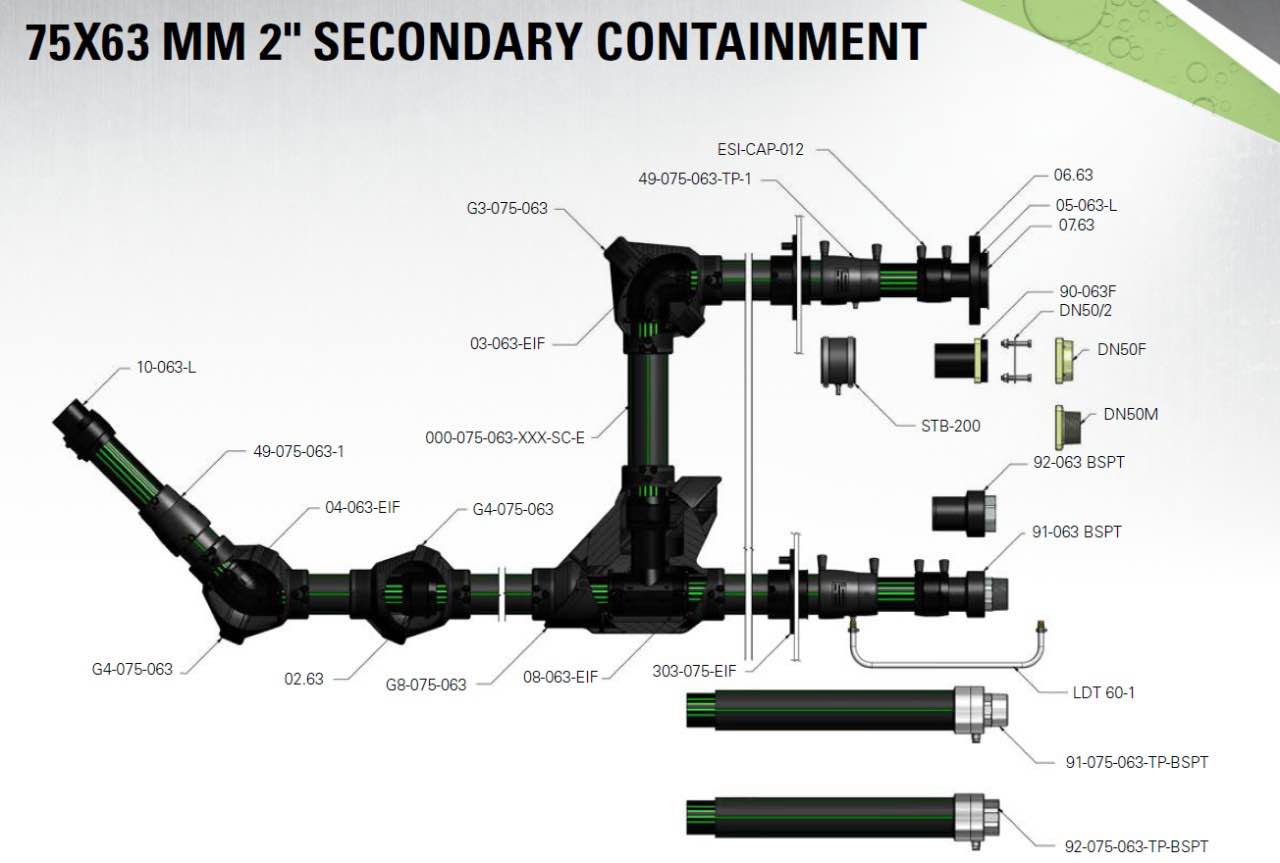

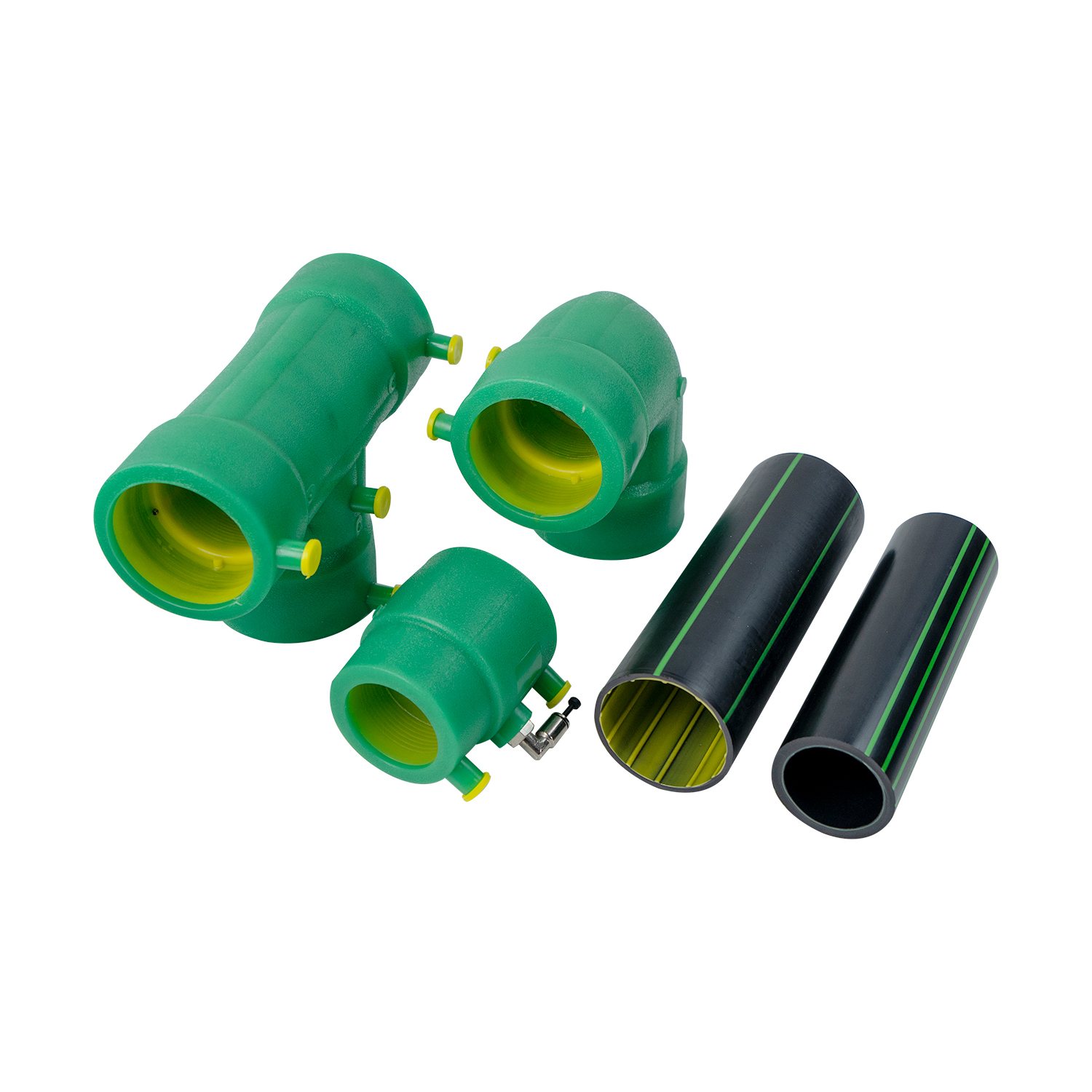

Double Protection PE UPP Pipe for Fuel Petrol Station

| Product Name: | HDPE Pipe FLW (Double Protection Buried Pipeline(non-conductive Static) Coils | Application: | petrol station |

|---|---|---|---|

| Struction: | Double Protection | Coils: | FLW Buried Pipeline(non-conductive Static) Coils |

| Straight Pipe: | FLW Buried Straight Pipeline(non-conductive Static) Coils | Material: | PE and PL Virgin Material |

Welcome to visit our factory or conduct a third-party audit.

Welcome to contact us for products details and professional service.

Please send email to: chuangrong@cdchuangrong.com

Product Description

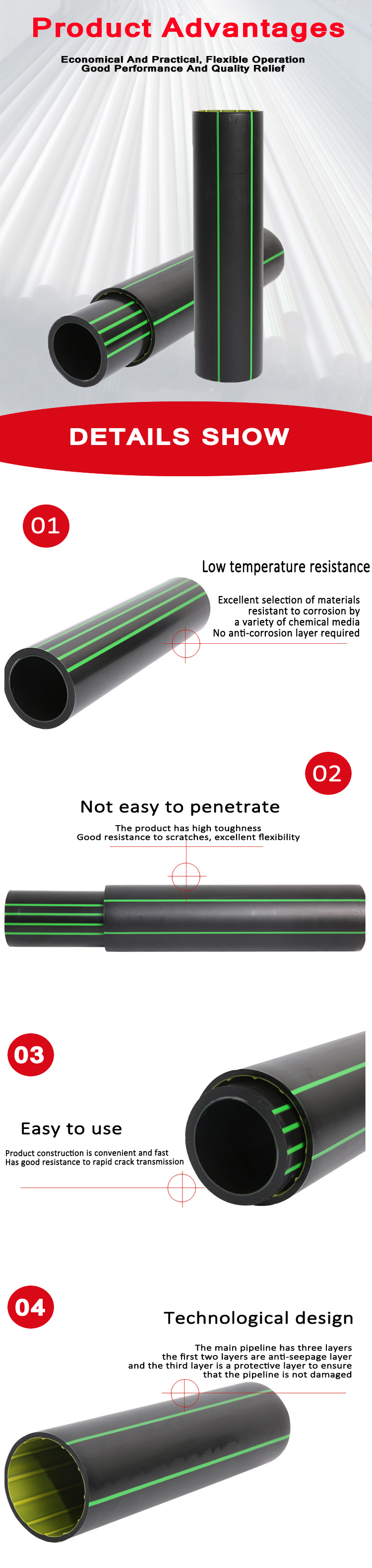

CHUANGRONG FLW buried pipeline system advantages:

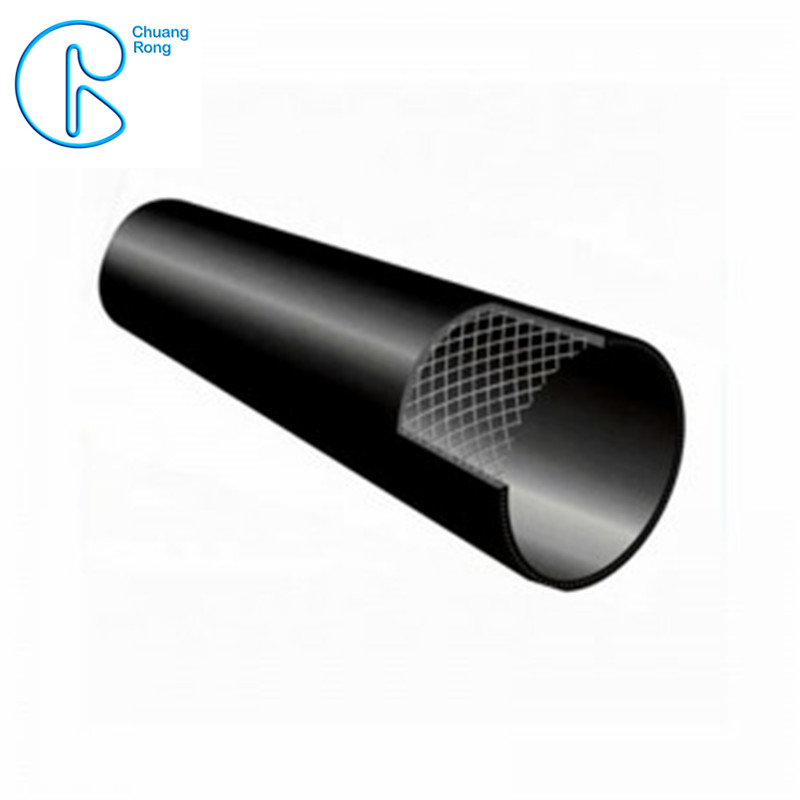

1. Double protection,Zero penetration:FLW oil pipeline system eliminates the possibility of fuel Spills into the environment, thus protecting the soil and water from pollution effectively.

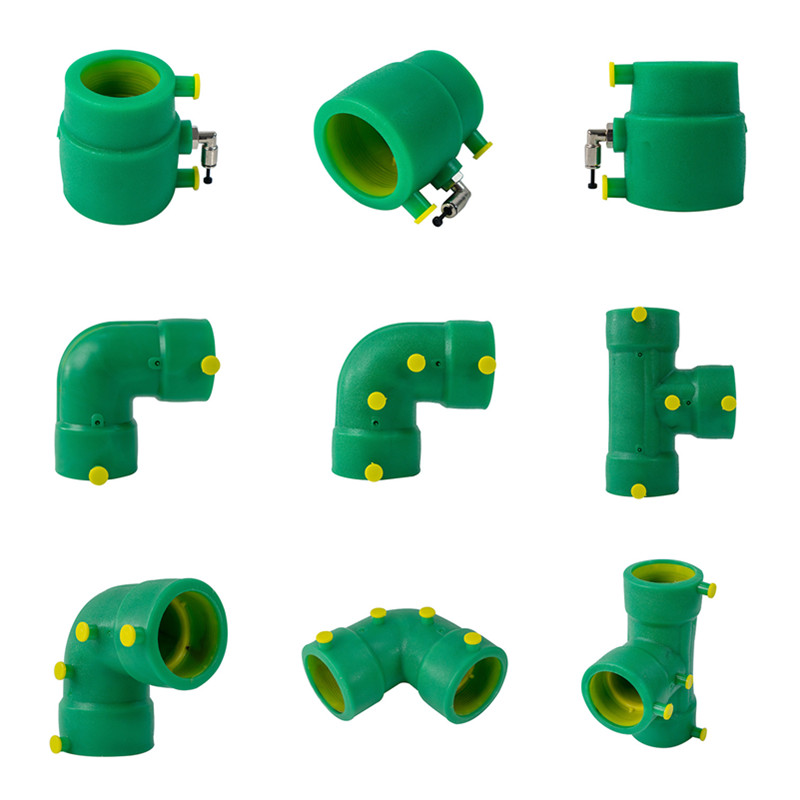

2. Safe and efficient installation, Low cost:FLW oil pipeline welding uses intelligent welding machine which lets double pipe connected completely. FLW oil pipeline system is without concrete trench and installation costs is greatly reduced.

3. 24 hours monitoring:FLW petroleum pipeline system has a leak detector, the pipeline for 24 hour monitoring. Once leaked, Indoor monitoring system will alarm.

4. Collision,Puncture,Tensile,Anti-ground motion capability.

If you have any questions, you can feel free to contact us in anytime .

Welcome to contact us for products details and professional service.

Please send email to: chuangrong@cdchuangrong.com or Tel: + 86-28-84319855

| Product Code | Description |

| FLW-54EC6 | OD54mm single layer pipe, 50m/Roll |

| FLW-63EC6 | OD63mm single layer pipe, 50m/Roll |

| FLW-65/54EC6 | Outer pipe with OD65mm,Inner pipe with OD54mm double layer pipe, 5.8m length |

| FLW-75/63EC6 | Outer pipe with OD75mm,Inner pipe with OD63mm double layer pipe, 5.8m length |

Low specific Weight

Excellent weldability

Smooth inside surface, no deposits and no overgrowth

Due to less frictional resistance, less pressure drop compared to metals

Suitable for food and potable water

Complies with the food stuff regulations

Approved and registered for potable water supply

Laying speed ease joining and reliability

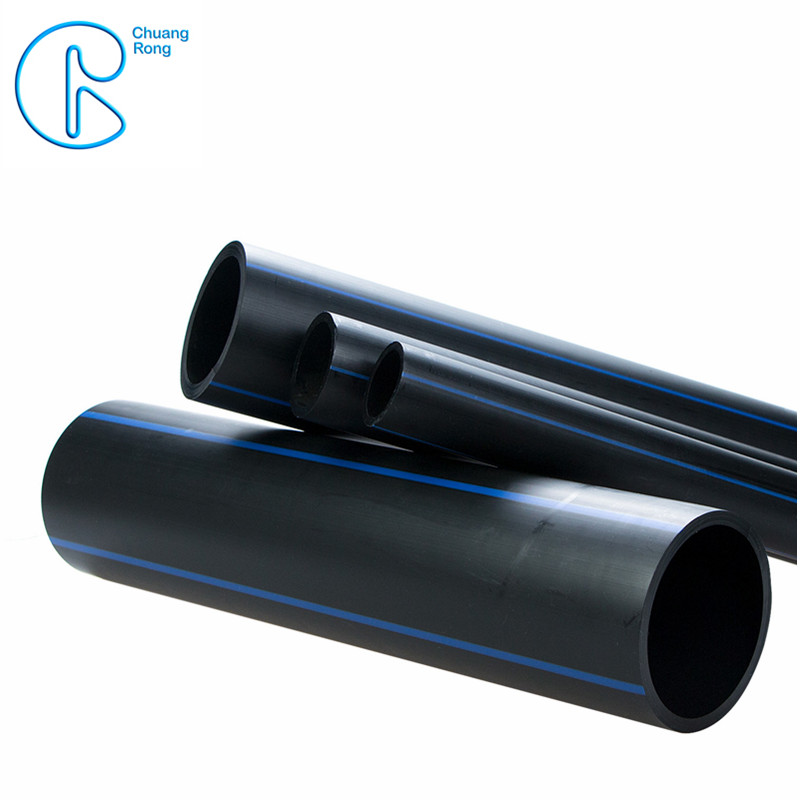

HDPE pipes have been in existence sicne the mid 50’s . The experience shows tha HDPE pipes is solution to most pipe problems being recogized by clients and engineering consultants as the ideal pipe material for many pressure and non pressure applications from water and gas distrutionto gavity , sewers and surface water drainage for both new & rehabilitation projects.

Application field: Drinking water supply pipe for urban and rural area, liquid transmission pipe in chemical, chemical fiber, food, forestry and metallurgy industry, waste water drainage pipe, mining slurry transmission pipe for mining field.

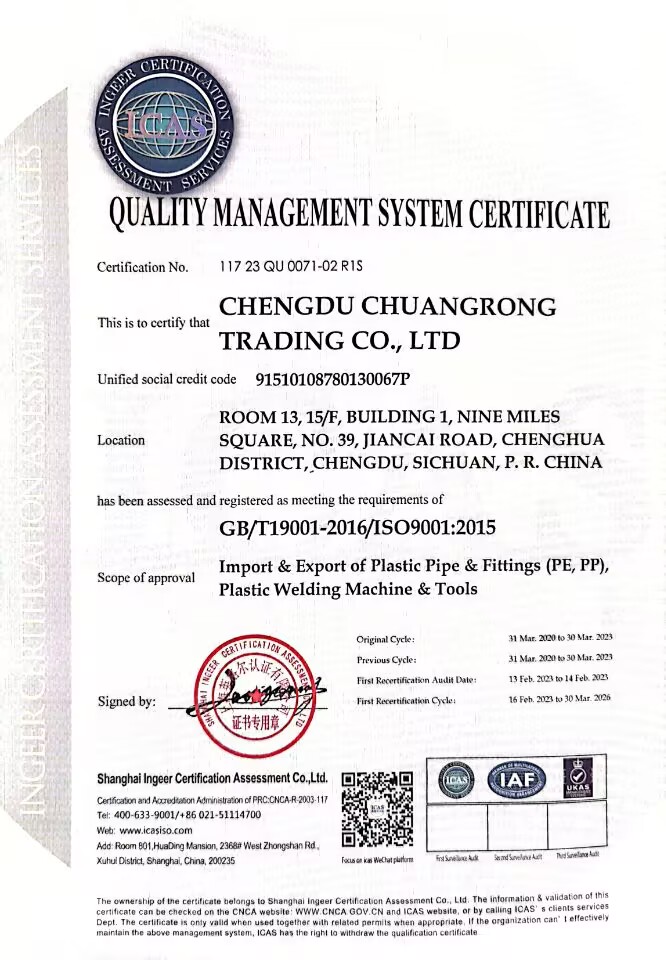

We can supply ISO9001-2015,WRAS, BV ,SGS, CE etc certification. All kinds of products are regularly conducted pressure-tight blasting test,longitudinal shrinkage rate test, quick stress crack resistance test, tensile test and melt index test, so as to ensure the quality of products totally reach the relevant standards from raw materials to finished products.

Send your message to us:

Products categories

-

Phone

-

E-mail

-

Whatsapp

-

Skype

-

Top