Welcome To CHUANGRONG

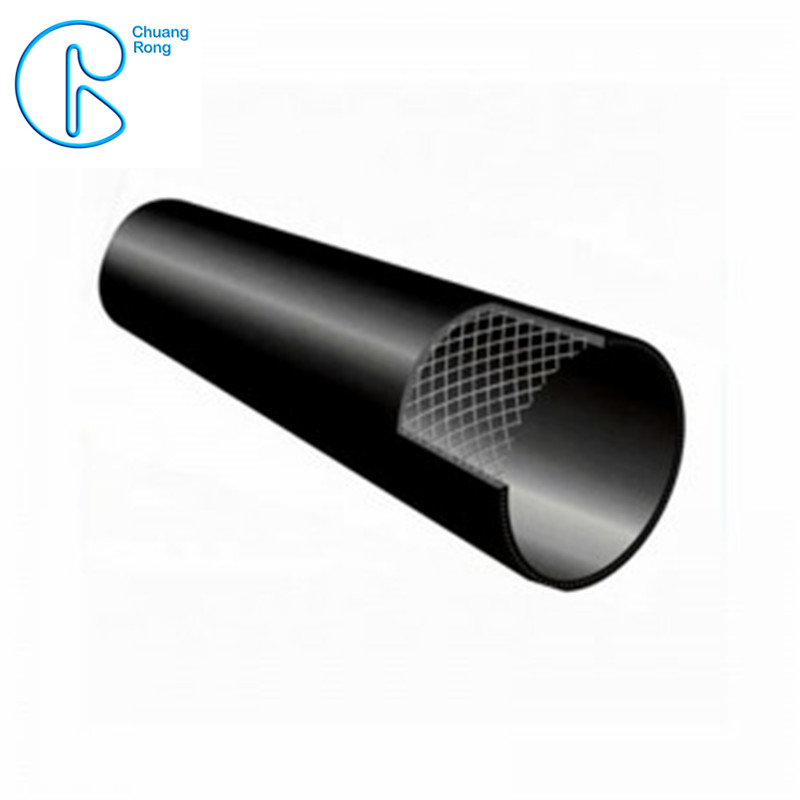

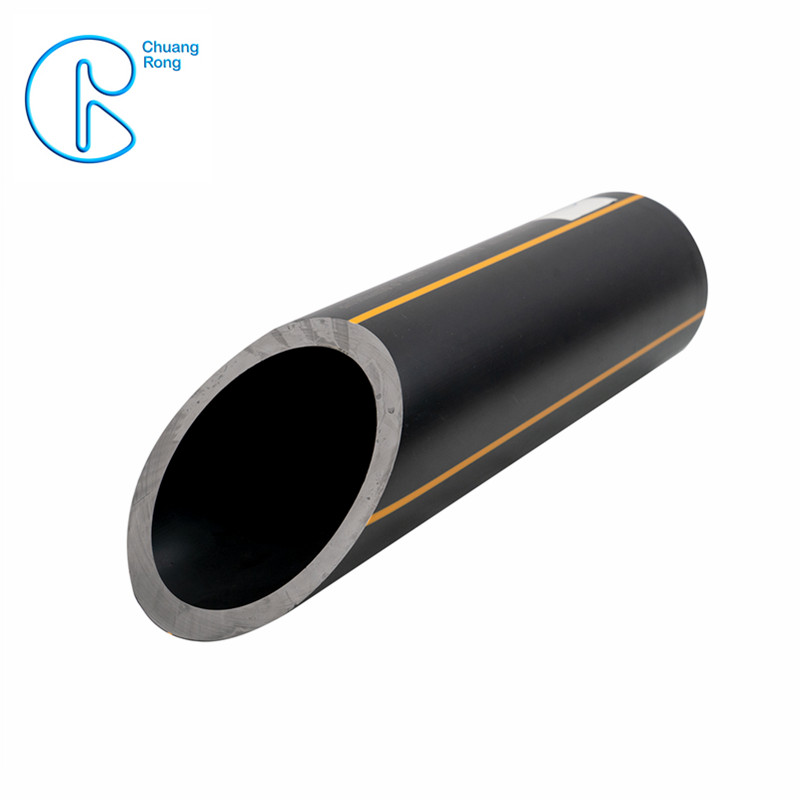

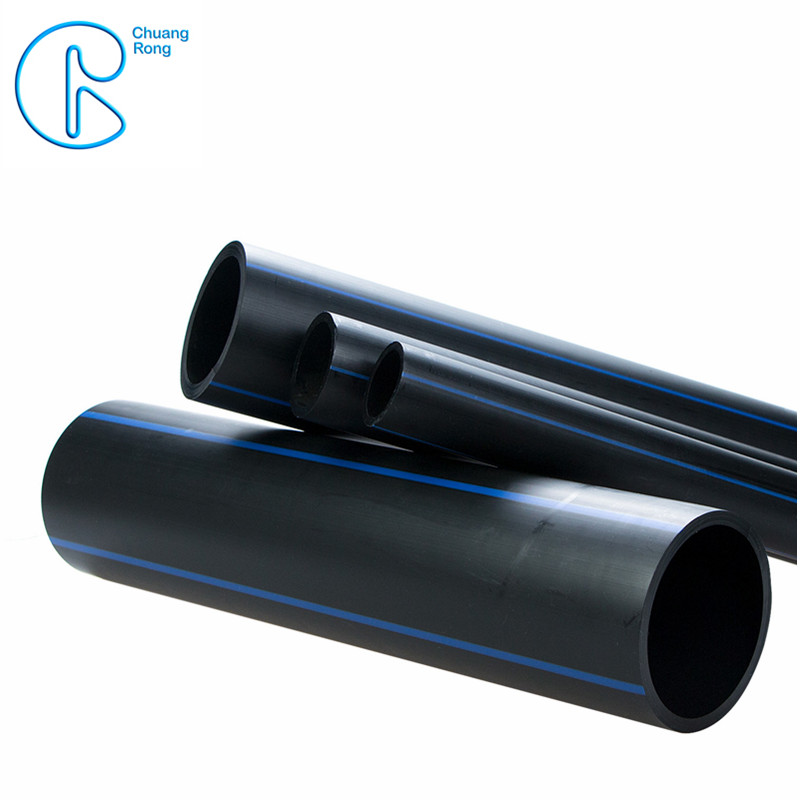

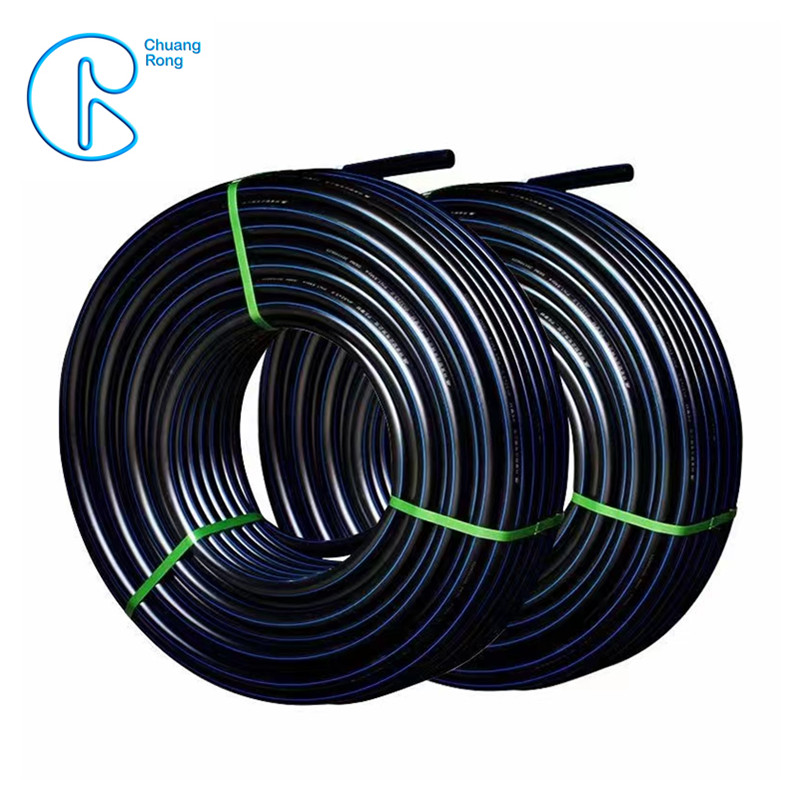

High Pressure Steel Plastic composite SRTP Pipe Steel Wire Reinforced HDPE Composite Pipe

Basic Information

CHUANGRONG always supplies the best products and price for customers. It gives customers good profit to develop their business with more confidence. If you are interested in our company and products, please do not hesitate to contact us for further information.

High Pressure Steel Plastic composite SRTP Pipe Steel Wire Reinforced HDPE Composite Pipe

| Product Name: | Steel Plastic composite pipe Steel Wire Reinforced HDPE composite pipe | Application: | Gas Oil Fuel Transportation, Irrigation and water supply |

|---|---|---|---|

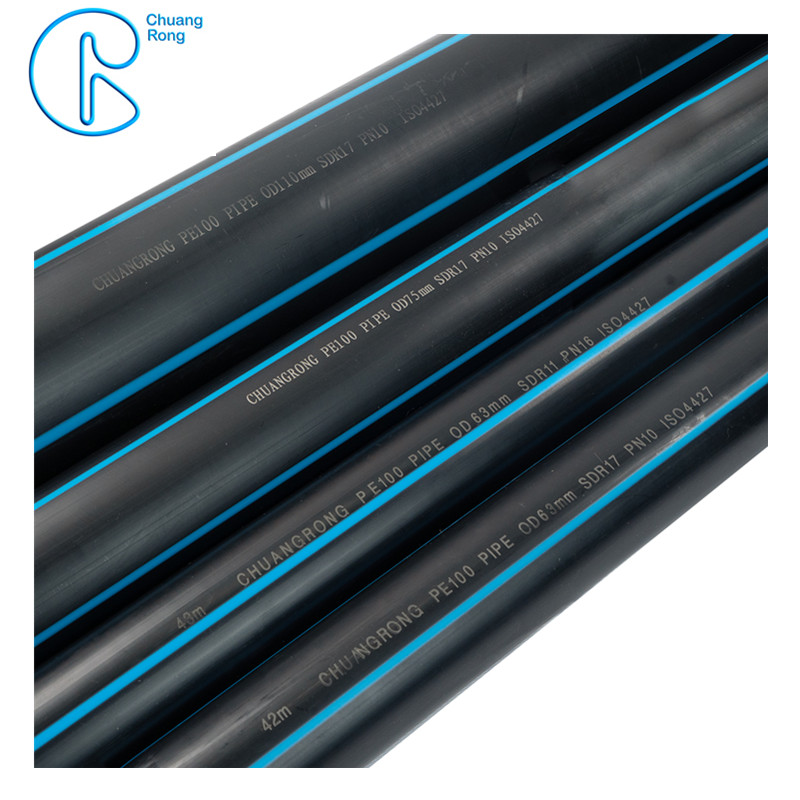

| Material: | 100% Virgin Material PE100 and steel wire | Standard: | CJ/T189-2007 , GB/T32439-2015 |

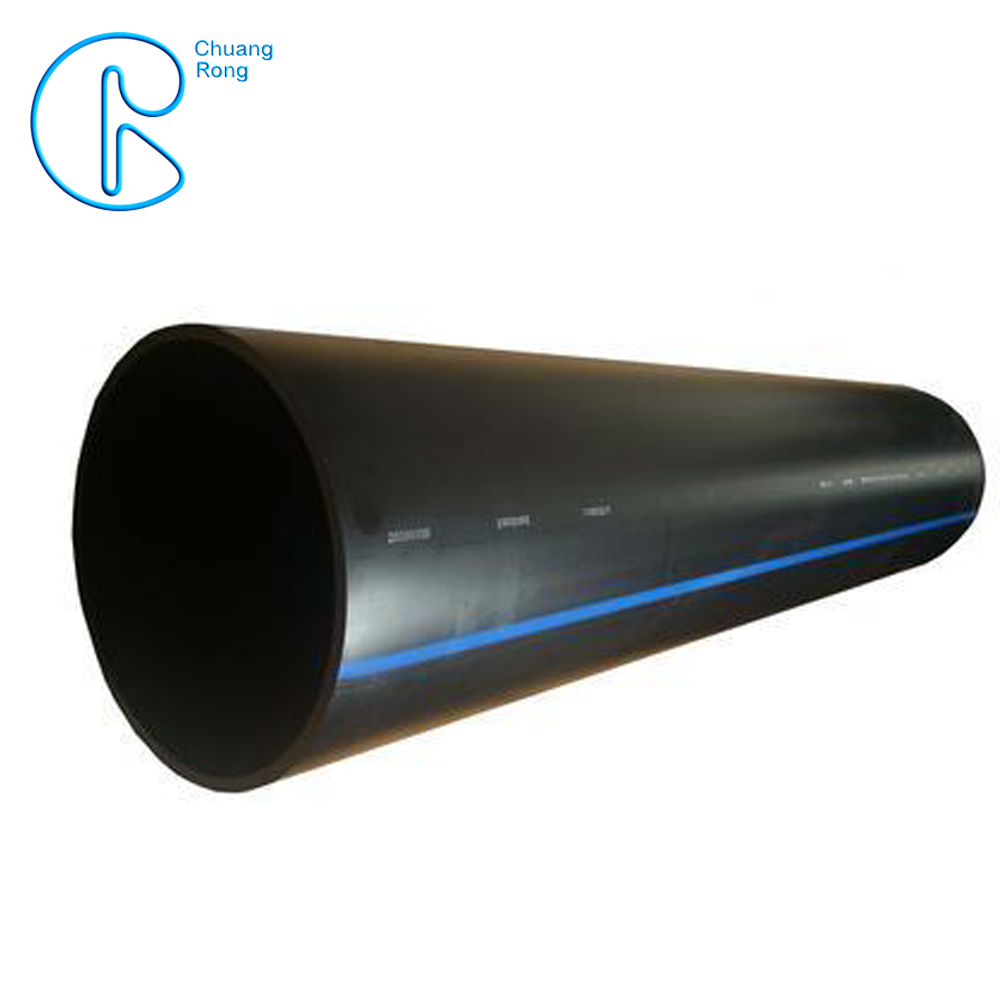

| Specification: | DN50-1000 mm | Quality Certification: | WRAS,CE,ISO,BV,SGS,Factory Test Report Etc |

Welcome to visit our factory or conduct a third-party audit.

Welcome to contact us for products details and professional service.

Please send email to: chuangrong@cdchuangrong.com

Specification

High Pressure Steel Plastic composite SRTP Pipe Steel Wire Reinforced HDPE Composite Pipe

| Pressure | 0.8Mpa | 1.0Mpa | 1.25Mpa | 1.6Mpa | 2.0Mpa | 2.5Mpa | 3.0Mpa | 3.5mpa | 4.0Mpa | 5.0Mpa | 6.3Mpa | 7.0Mpa |

| Specification(mm) | Wall Thickness(mm) | |||||||||||

| 50 | 4.5 | 5.0 | 5.5 | 5.5 | 5.5 | 6.0 | 8.5 | 9.0 | 9.5 | |||

| 63 | 4.5 | 5.0 | 5.5 | 5.5 | 5.5 | 6.5 | 8.5 | 9.0 | 10.0 | |||

| 75 | 5.0 | 5.0 | 5.5 | 6.0 | 6.0 | 9.5 | 9.5 | 9.5 | 10.5 | |||

| 90 | 5.5 | 5.5 | 5.5 | 6.0 | 6.0 | 10.0 | 10.5 | 10.5 | 11.5 | |||

| 110 | 5.5 | 5.5 | 7.0 | 7.0 | 7.5 | 8.5 | 8.5 | 11.0 | 12.0 | 12.0 | 12.0 | |

| 125 | 5.5 | 5.5 | 7.5 | 8.0 | 8.5 | 9.5 | 9.5 | 11.0 | 12.0 | 12.0 | 12.0 | |

| 140 | 5.5 | 5.5 | 8.0 | 8.5 | 9.0 | 9.5 | 9.5 | 11.0 | 12.0 | 13.0 | 13.0 | |

| 160 | 6.0 | 6.0 | 9.0 | 9.5 | 10.0 | 10.5 | 10.5 | 11.0 | 12.0 | 14.0 | 14.0 | |

| 200 | 6.0 | 6.0 | 9.5 | 10.5 | 11.0 | 12.0 | 12.5 | 13.0 | 13.0 | 15.0 | 15.0 | |

| 225 | 8.0 | 8.0 | 10.0 | 10.5 | 11.0 | 12.0 | 13.0 | 13.0 | 13.0 | |||

| 250 | 8.0 | 10.5 | 10.5 | 12.0 | 12.0 | 12.5 | 14.0 | 14.0 | 14.0 | 15.0 | ||

| 280 | 9.5 | 11.0 | 11.0 | 13.0 | 13.0 | 15.0 | 15.0 | 17.0 | ||||

| 315 | 9.5 | 11.5 | 11.5 | 13.0 | 13.0 | 15.0 | 15.0 | 18.0 | ||||

| 355 | 10.0 | 12.0 | 12.0 | 14.0 | 14.0 | 17.0 | 17.0 | 19.0 | ||||

| 400 | 10.5 | 12.5 | 12.5 | 15.0 | 15.0 | 17.0 | 17.0 | |||||

| 450 | 11.5 | 13.5 | 13.5 | 16.0 | 16.0 | 18.0 | ||||||

| 500 | 12.5 | 15.5 | 15.5 | 18.0 | 18.0 | 22.0 | ||||||

| 560 | 17.0 | 20.0 | 20.0 | 22.0 | 22.0 | |||||||

| 630 | 20.0 | 23.0 | 23.0 | 26.0 | 26.0 | |||||||

| 710 | 23.0 | 26.0 | 28.0 | 30.0 | ||||||||

| 800 | 27.0 | 30.0 | 32.0 | 34.0 | ||||||||

| 900 | 29.0 | 33.5 | 35.0 | 38.0 | ||||||||

| 1000 | 34.0 | 37.0 | 40.0 | |||||||||

Product Description

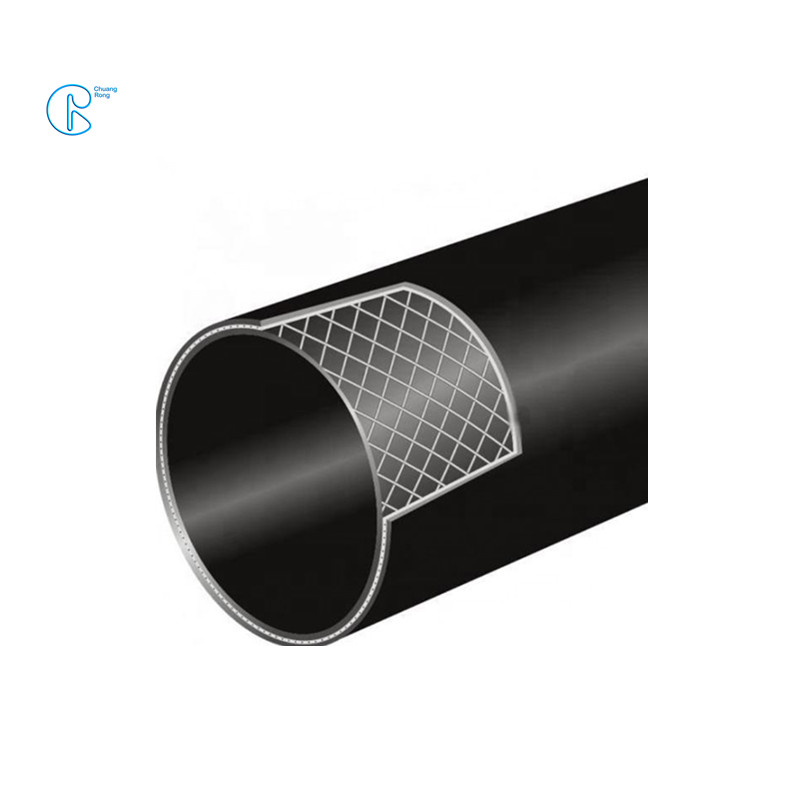

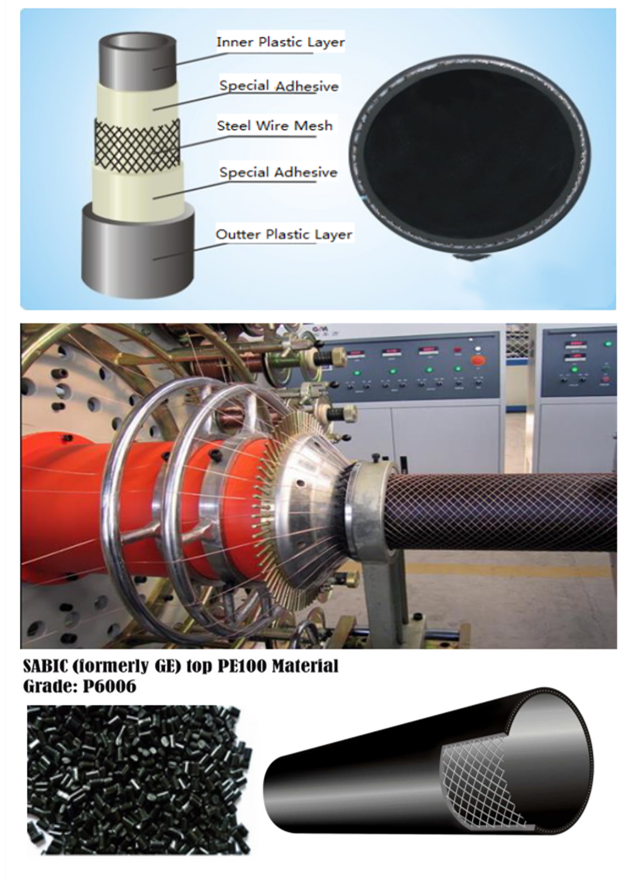

Steel mesh reinforced HDPE Composite pipe is compounded special hot adhesive layer to plastic.The inner surface of the pipe has the same features of corrosion resistance and wear resistance.The inner wall is smooth for transportation without scaling, no wax, corrosion resistance and energy saving.This pipe is more economical and convenient for underground transportation and corrosive environmental conditions.Furthermore,the pipe has excellent seismic resistance, which almost cannot be damaged in earthquakes. Because of the reinforced effect of steel wire mesh,it has more outstanding ability to adapt to land subsidence and other conditions.Based on above advantages,this kind of pipe is selected as the buried underground water pipe of national stadium during the construction of Olympic venues.

Features

1. Higher strength,rigidity and impact resistance comparing with PE solid wall pipes.

2. Double-sided corrosion resistance,same to the corrosion resistance performance of plastic pipe.

3. To increase the temperature application condition due to low heat conductivity coefficient.No need heat protection of outer wall in winter,and no moisture condensation in summer.

4. Smooth inner wall,no scaling, reducing 30% water head loss comparing with steel pipe.

5 The pipes are connected by the way of electrofusion,which enjoys mature technology,easy and secure connec- tion,strong performance of axial tensile,and various pipe fitting specification.

6. Light weight,convenient transportation and construction,and high overall reliability of pipes.Under normal conditions,the service life can reach 50 years.

7.It is the best substitute for galvanized pipes due to its low cost and sanitation.

8.The structure is made by winding the spiral steel wire,which can both enjoy the characters of low linear expan- sion coefficient and good flexibility in the axial direction,so well improve the performance of environment adapt- ability.

9. It can be well suitable for the application fields of long-distance water transportation under complex working conditions.

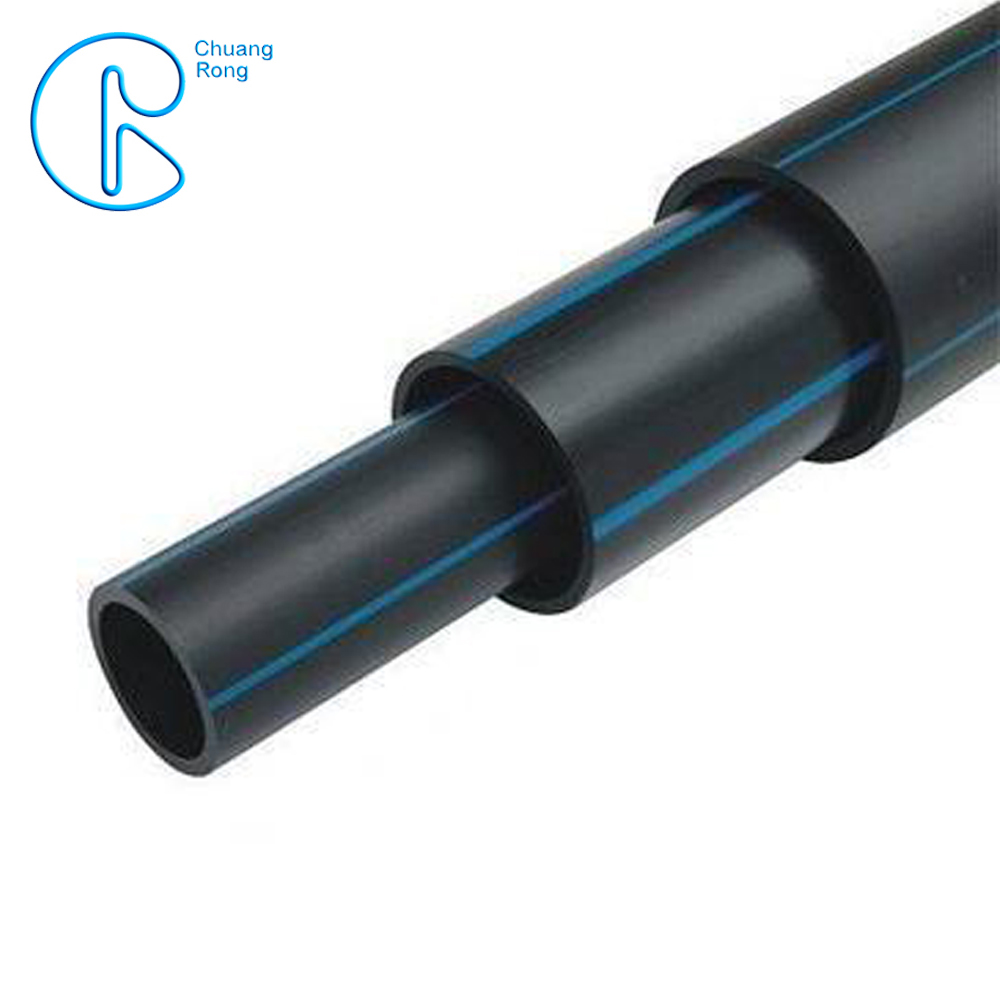

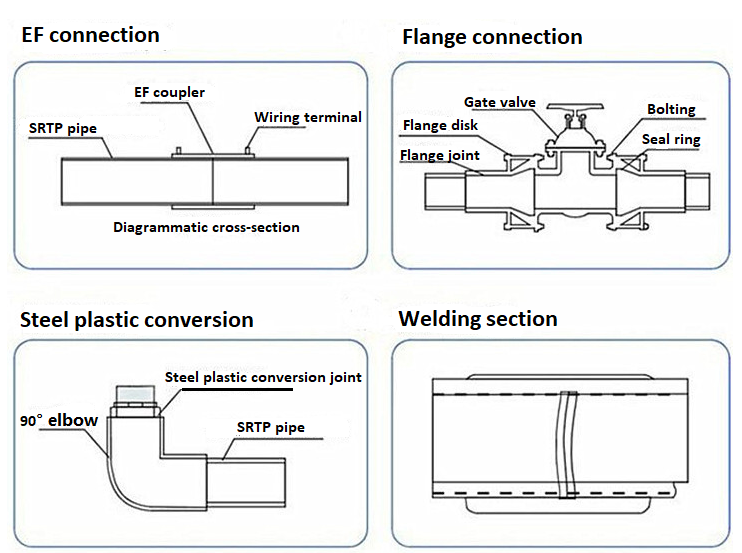

Connection Methods

Electro Fusion Joint

This technique of heat fusion joining is somewhat different from the conventional fusion joining.The main difference between conventional heat fusion and electro fusion is the method by which the heat is applied. In conventional heat fusion joining, a heating tool is used to heat the pipe and fitting surfaces.The electro fusion joint is heated internally,either by a wire coil at the interface of the joint or, as in one design, by a conductive polymer.Heat is created as an electric current is applied to the conductive material in the fitting. General steps to be followed when performing electro fusion joining are:

1.Prepare the pipes

2.Clamp the fittings and pipe(s)

3.Apply the electric current

4.Cold and remove the clamps

Application

Steel mesh reinforced HDPE Composite pipe is a new type of pipeline with excellent performance, widely used in oil fields, power plants, chemical and petrochemical enterprises, water companies, municipal gas, seawater pipeline and other fields.

CHUANGRONG has an excellent staff team with rich experience. Its principal is Integrity, Professional and Efficient. It has established business relationship with more than 80 countries and zones in relative industry. Such as United States, Chile, Guyana, The United Arab Emirates, Saudi Arabia, Indonesia, Malaysia,Bangladesh, Mongolia, Russia, Africa and so on.

Welcome to contact us for products details and professional service.

Please send email to: chuangrong@cdchuangrong.com or Tel: + 86-28-84319855

Send your message to us:

Products categories

-

Phone

-

E-mail

-

Whatsapp

-

Skype

-

Top