Welcome To CHUANGRONG

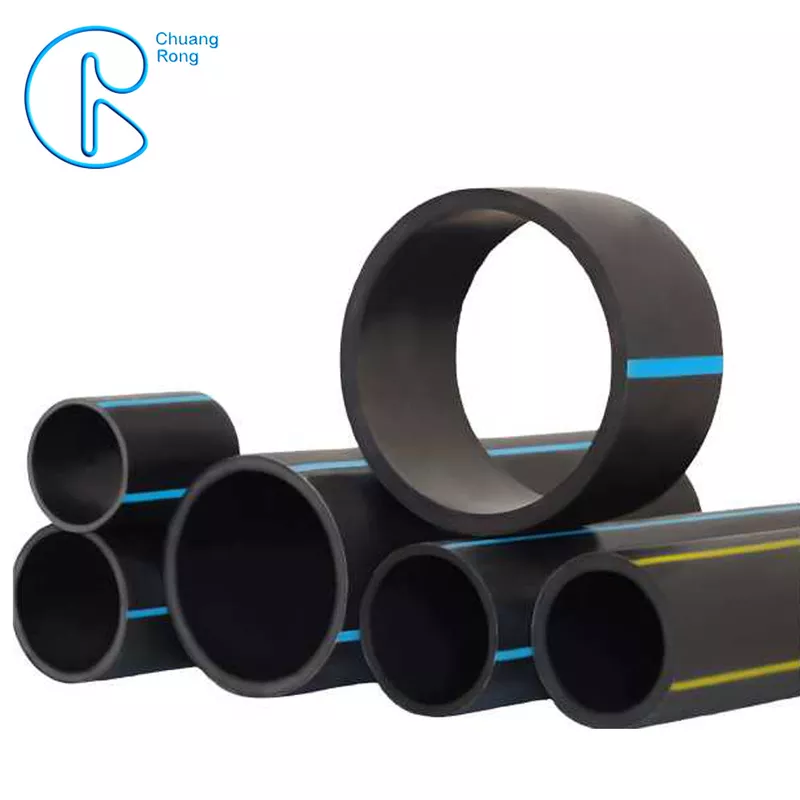

Large Size PE100 DN1200 PN16 Hdpe Plastic Water Pipe With CE Approved

Producion Information

CHUANGRONG is a share industry and trade integrated company, established in 2005 which focused on the production of HDPE Pipes, Fittings & Valves, PPR Pipes, Fittings & Valves, PP compression fittings & Valves, and sale of Plastic Pipe Welding machines, Pipe Tools, Pipe Repair Clamp and so on.

Large Size PE100 DN1200 PN16 Hdpe Plastic Water Pipe With CE Approved

|

Products Details |

Company/Factory Strength |

||

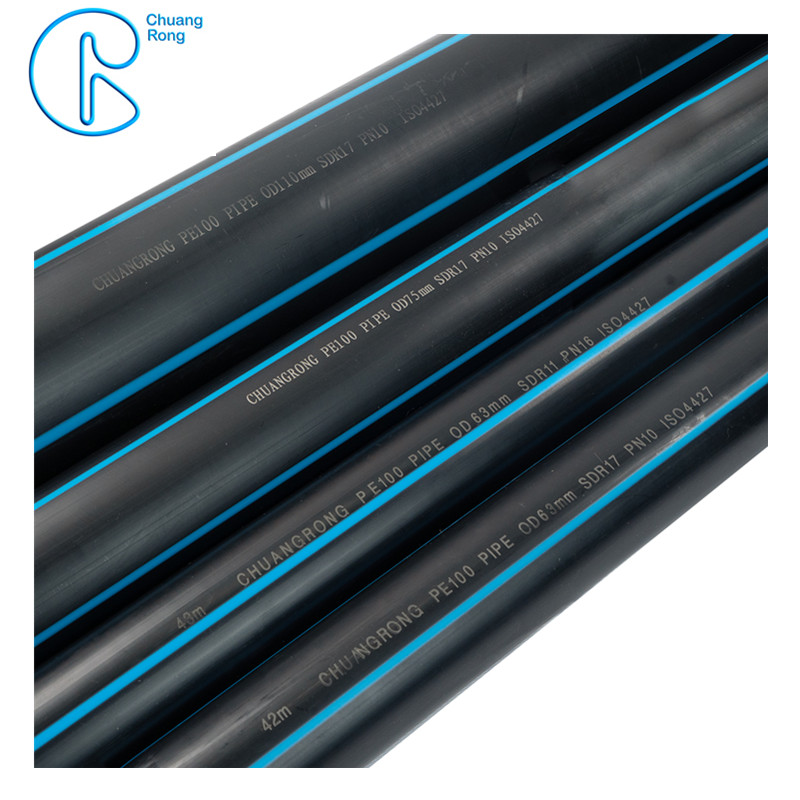

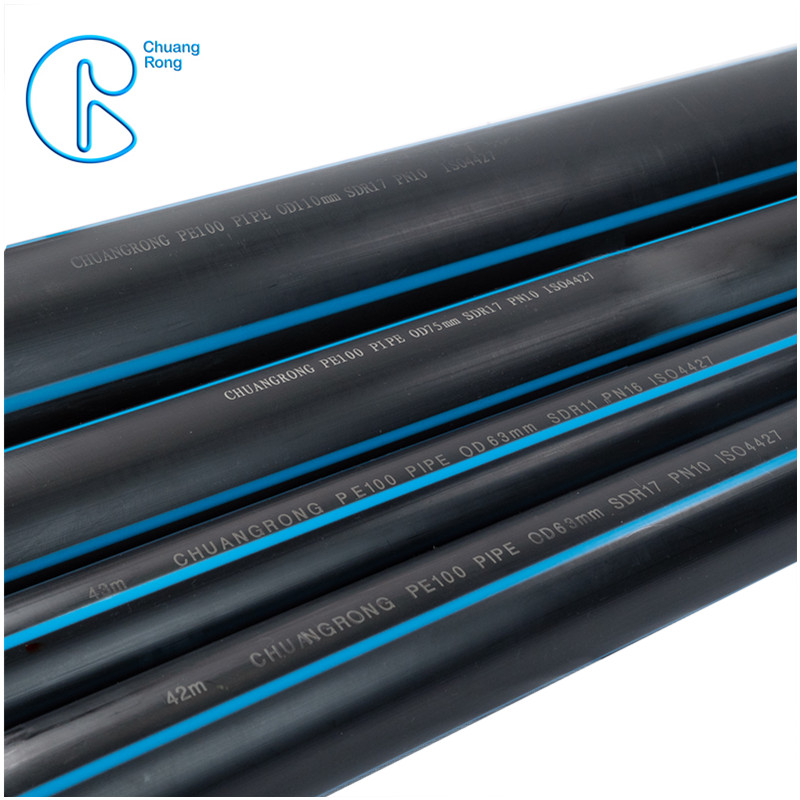

| Name | High Density Polyethylene (HDPE) Drinking Water Pipe | Production Capacity | 100,000 Ton/Year |

| size | DN20-1600mm | Sample | Free sample available |

| Pressure | PN4- PN25, SDR33-SDR7.4 | Delivery time | 3-15 days, depending on the quantity |

| Standards | ISO 4427, ASTM F714, EN 12201, AS/NZS 4130, DIN 8074, IPS | Test/inspection | National standard laboratory, Pre-delivery inspection |

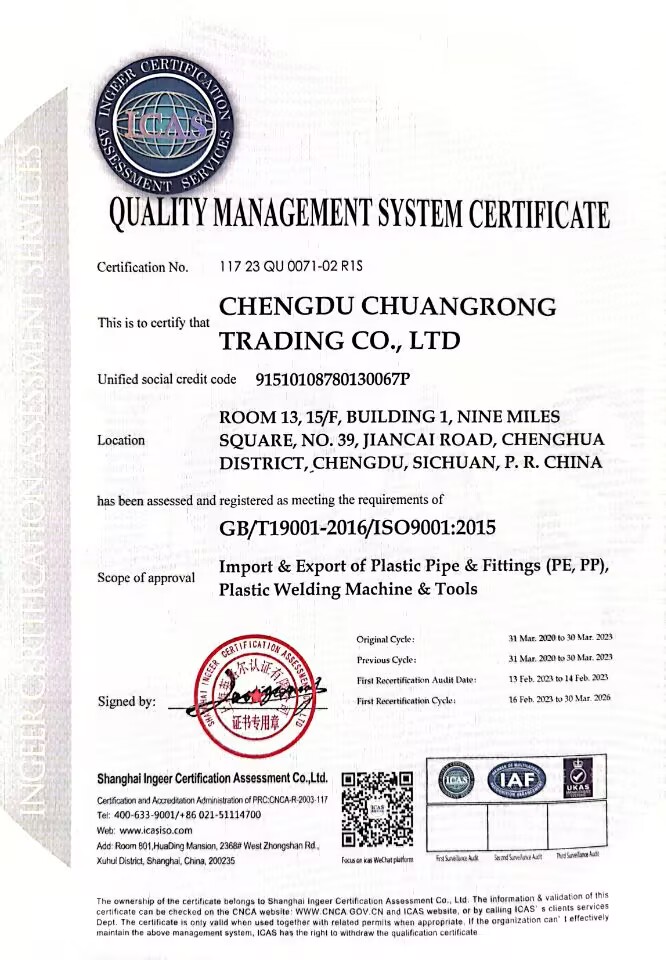

| Raw Material | 100% Virgin l PE80, PE100, PE100-RC | Certificates | ISO9001, CE, WRAS, BV, SGS |

| Color | Black with blue stripes, Blue or others colors | Warranty | 50 years with normal use |

| Packing | 5.8m or 11.8m/length, 50-200m/roll, for DN20-110mm. | Quality | QA & QC system, Ensure traceability of each process |

| Application |

Drinking water, Fresh water, Drainage, Oil and Gas, Mining, Dredging, Marine, Irrigation, Industry, Chemical, Fire fighting... |

Service | R&D, production, sale and installation, after-sales service |

|

Matching products: Butt fusion, Socket fusion, Electrofusion, Drainage, Fabricated, Machined fitting, Compression fittings, Plastic Welding machines and tools, etc. |

|||

Welcome to visit our factory or conduct a third-party audit.

Welcome to contact us for products details and professional service.

Please send email to: chuangrong@cdchuangrong.com

Product Description

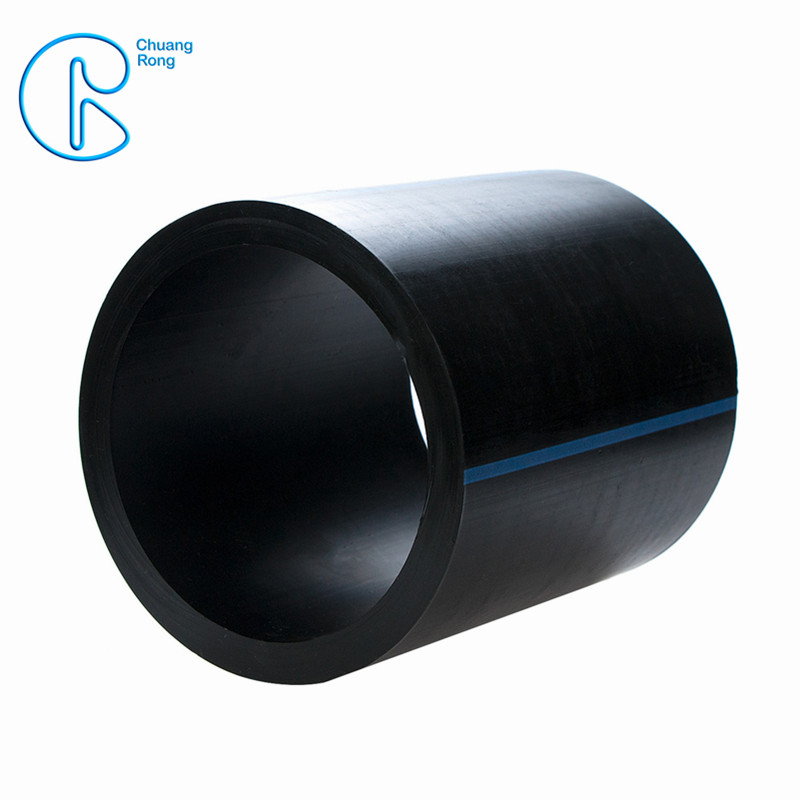

High Density Polyethylene (HDPE) piping systems are used all over the world for the supply and conveying of several kinds of media, including liquid, gas and powers as well as in mining and quarry applications.

High Density Polyethylene (HDPE) pipework systems have the main advantages over steel and ductile iron systems if lightness of weight and freedom from corrosion. The rapid growth in use of polyethylene is due in part to benefits over steel and iron systems, but possibly more to the development of several advanced and easy jointing techniques. Polyethylene has very good fatigue strength and special provision for surges frequently allowed when designing other thermoplastic pipework systems (as PVC) are not normally necessary.

High Density Polyethylene (HDPE) pipes are produced in size up to 2500mm in diameter, with nominal pressure rating PN4, PN6, PN10, up to PN25 (other pressure ratings also available). All pipes and fittings are manufactured in accordance with current EN12201, DIN 8074, ISO 4427/ 1167 and SASO Draft No.5208.

High Density Polyethylene (HDPE) piping system are used worldwide for conveying of water as well as for the transportation of hazardous fluids.

Welcome to contact us for products details and professional service.

Please send email to: chuangrong@cdchuangrong.com or Tel: + 86-28-84319855

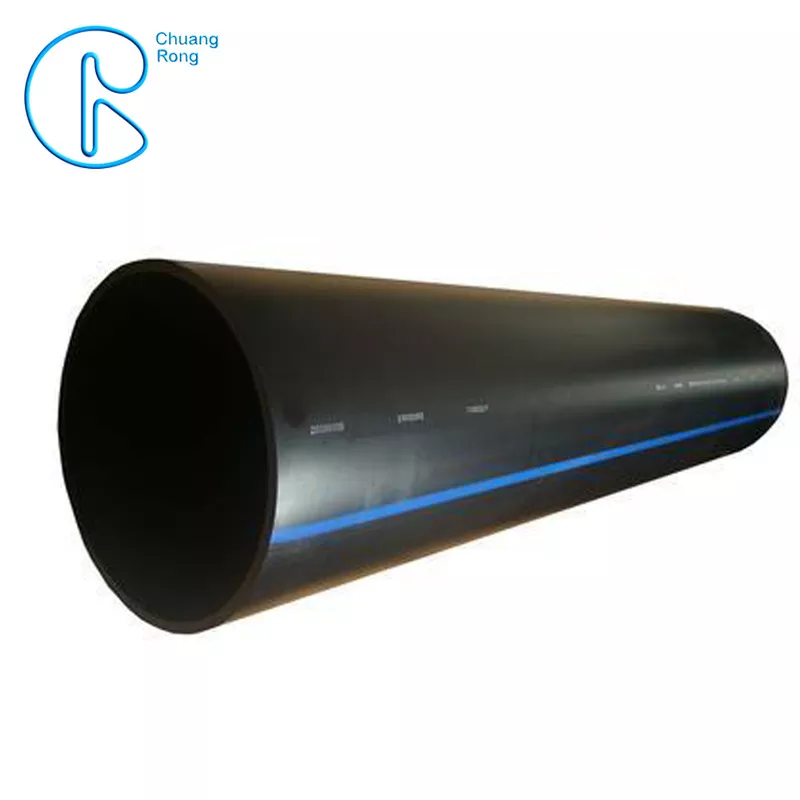

PE100 DN1200 PN16 Hdpe Plastic Water Pipe

|

PE100 |

0.4MPa |

0.5MPa |

0.6MPa |

0.8MPa |

1.0MPa |

1.25MPa |

1.6MPa |

2.0MPa |

2.5MPa |

|

Outside Diameter (mm) |

PN4 |

PN5 |

PN6 |

PN8 |

PN10 |

PN12.5 |

PN16 |

PN20 |

PN25 |

|

SDR41 |

SDR33 |

SDR26 |

SDR21 |

SDR17 |

SDR13.6 |

SDR11 |

SDR9 |

SDR7.4 |

|

|

Wall Thickness (en) |

|||||||||

|

20 |

- |

- |

- |

- |

- |

- |

2.0 |

2.3 |

3.0 |

|

25 |

- |

- |

- |

- |

- |

2.0 |

2.3 |

3 |

3.5 |

|

32 |

- |

- |

- |

- |

2.0 |

2.4 |

3.0 |

3.6 |

4.4 |

|

40 |

- |

- |

- |

2.0 |

2.4 |

3.0 |

3.7 |

4.5 |

5.5 |

|

50 |

- |

- |

2.0 |

2.4 |

3.0 |

3.7 |

4.6 |

5.6 |

6.9 |

|

63 |

- |

- |

2.5 |

3.0 |

3.8 |

4.7 |

5.8 |

7.1 |

8.6 |

|

75 |

- |

- |

2.9 |

3.6 |

4.5 |

5.6 |

6.8 |

8.4 |

10.3 |

|

90 |

- |

- |

3.5 |

4.3 |

5.4 |

6.7 |

8.2 |

10.1 |

12.3 |

|

110 |

- |

- |

4.2 |

5.3 |

6.6 |

8.1 |

10.0 |

12.3 |

15.1 |

|

125 |

- |

- |

4.8 |

6.0 |

7.4 |

9.2 |

11.4 |

14 |

17.1 |

|

140 |

- |

- |

5.4 |

6.7 |

8.3 |

10.3 |

12.7 |

15.7 |

19.2 |

|

160 |

- |

- |

6.2 |

7.7 |

9.5 |

11.8 |

14.6 |

17.9 |

21.9 |

|

180 |

- |

- |

6.9 |

8.6 |

10.7 |

13.3 |

16.4 |

20.1 |

24.6 |

|

200 |

- |

- |

7.7 |

9.6 |

11.9 |

14.7 |

18.2 |

22.4 |

27.4 |

|

225 |

- |

- |

8.6 |

10.8 |

13.4 |

16.6 |

20.5 |

25.2 |

30.8 |

|

250 |

- |

- |

9.6 |

11.9 |

14.8 |

18.4 |

22.7 |

27.9 |

34.2 |

|

280 |

- |

- |

10.7 |

13.4 |

16.6 |

20.6 |

25.4 |

31.3 |

38.3 |

|

315 |

7.7 |

9.7 |

12.1 |

15 |

18.7 |

23.2 |

28.6 |

35.2 |

43.1 |

|

355 |

8.7 |

10.9 |

13.6 |

16.9 |

21.1 |

26.1 |

32.2 |

39.7 |

48.5 |

|

400 |

9.8 |

12.3 |

15.3 |

19.1 |

23.7 |

29.4 |

36.3 |

44.7 |

54.7 |

|

450 |

11 |

13.8 |

17.2 |

21.5 |

26.7 |

33.1 |

40.9 |

50.3 |

61.5 |

|

500 |

12.3 |

15.3 |

19.1 |

23.9 |

29.7 |

36.8 |

45.4 |

55.8 |

- |

|

560 |

13.7 |

17.2 |

21.4 |

26.7 |

33.2 |

41.2 |

50.8 |

62.5 |

- |

|

630 |

15.4 |

19.3 |

24.1 |

30 |

37.4 |

46.3 |

57.2 |

70.3 |

- |

|

710 |

17.4 |

21.8 |

27.2 |

33.9 |

42.1 |

52.2 |

64.5 |

79.3 |

- |

|

800 |

19.6 |

24.5 |

30.6 |

38.1 |

47.4 |

58.8 |

72.6 |

89.3 |

- |

|

900 |

22 |

27.6 |

34.4 |

42.9 |

53.3 |

66.2 |

81.7 |

- |

- |

|

1000 |

24.5 |

30.6 |

38.2 |

47.7 |

59.3 |

72.5 |

90.2 |

- |

- |

|

1200 |

29.4 |

36.7 |

45.9 |

57.2 |

67.9 |

88.2 |

- |

- |

- |

|

1400 |

34.3 |

42.9 |

53.5 |

66.7 |

82.4 |

102.9 |

- |

- |

- |

|

1600 |

39.2 |

49 |

61.2 |

76.2 |

94.1 |

117.6 |

- |

- |

- |

Welcome to contact us for products details and professional service.

Please send email to: chuangrong@cdchuangrong.com or Tel: + 86-28-84319855

HDPE pipes have been in existence since the mid 50′s. The experience shows that HDPE pipes is the solution to most pipe problems being recognized by clients and engineering consultants as the ideal pipe material for many pressure and non pres-sure applications from water and gas distribution to gravity, Sewers and surface water drainage for both new & Rehabilitation Projects. Chuangrong polyethylene pipes is based on a polytholefin thermoplastic resin which is also a physiologically non-toxic material, therefore, it is suitable for a wide range of applications.

Suitable for:

Water Supply. Chuangrong HDPE pipes are made from material meeting the toxicity requirement of the WHO and this can be used for transportation of drinking water.

-Pipes and fittings with pressure ratings of SDR 7.4 up to SDR 41 for water mains as well as distribution piping systems and service lines.

-Drain pipes and fittings for spring water chamber pipes.

-Ascending pipes for wells.

In contrast for pipes mad of steel or ductile iron, HDPE piping systems are light weight and corrosion resistant. Neither sour soils nor “aggressive” water will have no effect to the material. Additionally,corrosion products,which often impair the operability of the piping system, are avoided. In comparison to PVC pipes, HDPE pipes are more flexible and offer high impact resistance even in zero temperatures. The pipes may be adapted easily to the trench layout without employing additional fittings.On the other hand, fracture risks due to extreme handling conditions on the construction site are minimized. HDPE piping systems (spigot and socket joints) offer a range of longitudinal frictional connection methods. Thus, the installation of anchors or thrust blocks is not necessary and a leak proof piping system with a long life is guaranteed.

CHUAGNRONG owns more 100 sets pipe production lines that are advanced at domestic and abroad,200 sets of fitting production equipment. The production capacity reaches more than 100 thousand tons. Its main contain 6 systems of water, gas, dredging, mining, irrigation and electricity, more than 20 series and more than 7000 specifications.

ISO9001-2015,WRAS, BV ,SGS, CE etc certification.All kinds of products are regularly conducted pressure-tight blasting test,longitudinal shrinkage rate test, quick stress crack resistance test, tensile test and melt index test, so as to ensure the quality of products totally reach the relevant standards from raw materials to finished products.

Send your message to us:

Products categories

-

Phone

-

E-mail

-

Whatsapp

-

Skype

-

Top