Welcome To CHUANGRONG

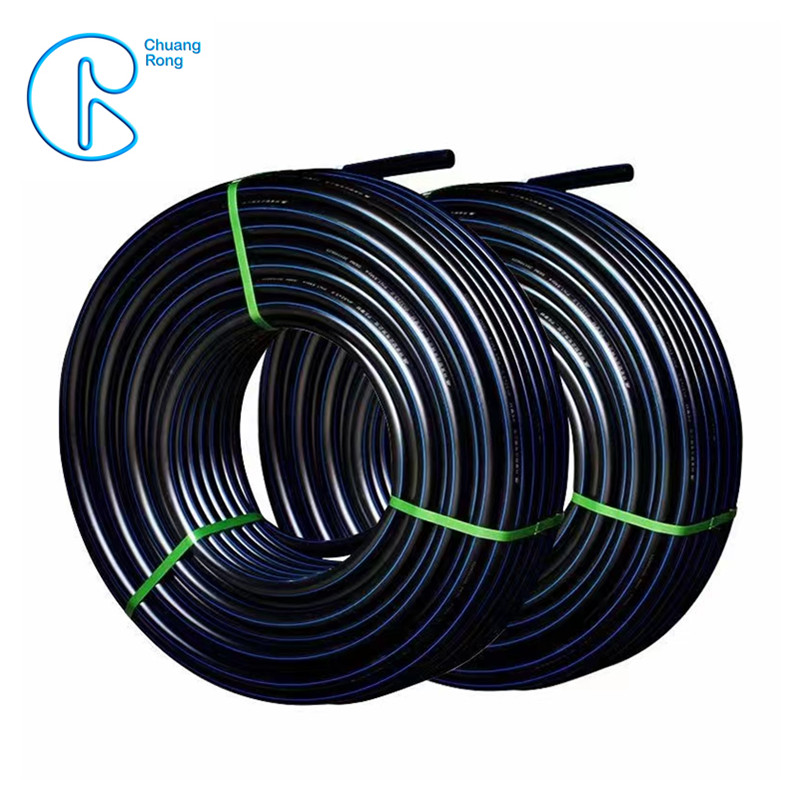

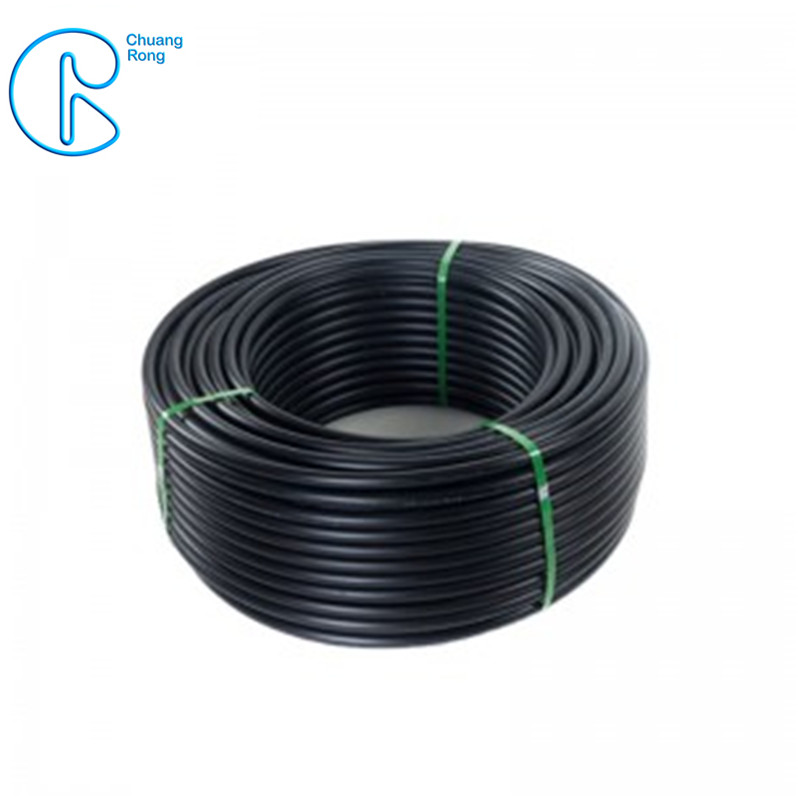

OEM ODM Supported HDPE SDR26-SDR11 Irrigation or Water Coil Pipe With WRAS Certificated

Detail Information

CHUANGRONG and its affiliated companies specialize in the R&D, production, sale and installation of new-type plastic pipes and fittings. It owned five factories, one of the largest manufacturer and supplier of plastic pipes and fittings in China. Furthermore, the company owns more 100 sets pipe production lines that are advanced at domestic and abroad,200 sets of fitting production equipment. The production capacity reaches more than 100 thousand tons. Its main contain 6 systems of water, gas, dredging, mining, irrigation and electricity, more than 20 series and more than 7000 specifications.

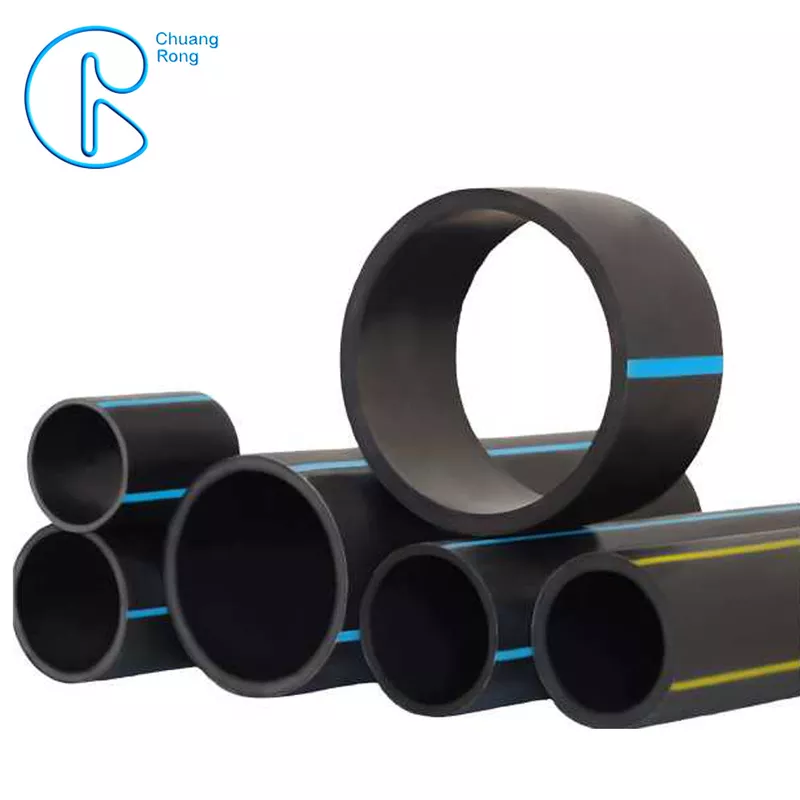

HDPE Irrigation or Water Coil Pipe

|

Products Details |

Company/Factory Strength |

||

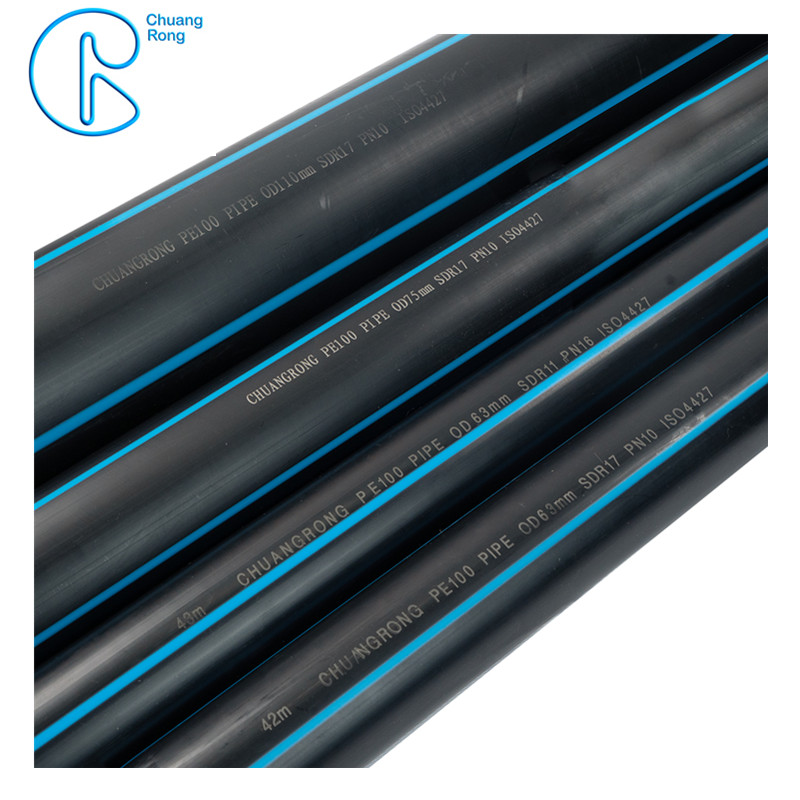

| Name | HDPE Irrigation or Water Coil Pipe | Production Capacity | 100,000 Ton/Year |

| size | DN20-110mm | Sample | Free sample available |

| Pressure | PN4- PN25, SDR33-SDR7.4 | Delivery time | 3-15 days, depending on the quantity |

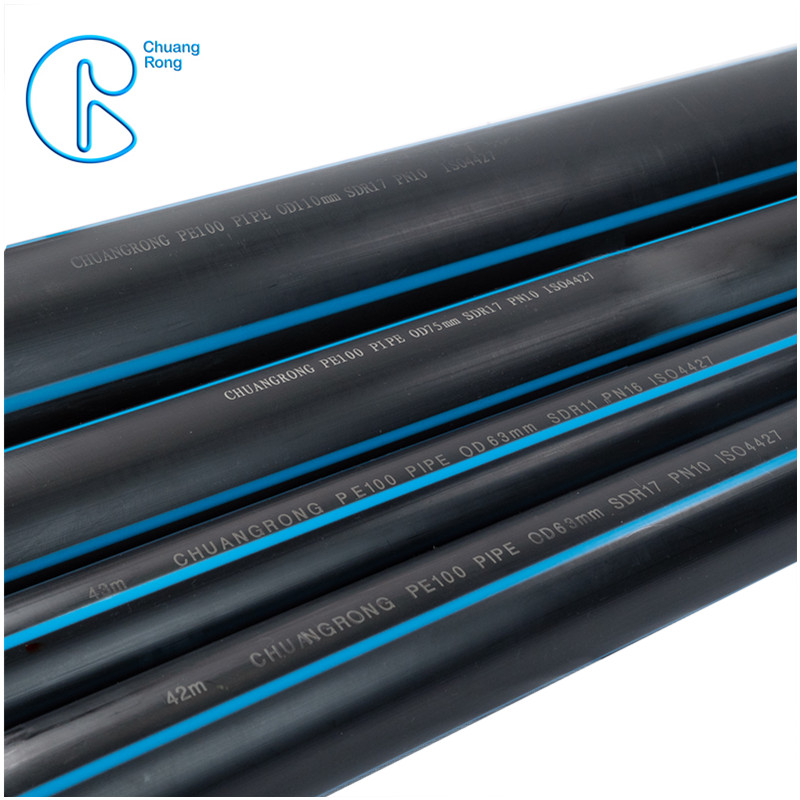

| Standards | ISO 4427, ASTM F714, EN 12201, AS/NZS 4130, DIN 8074, IPS | Test/inspection | National standard laboratory, Pre-delivery inspection |

| Raw Material | 100% Virgin l PE80, PE100, PE100-RC | Certificates | ISO9001, CE, WRAS, BV, SGS |

| Color | Black with blue stripes, Blue or others colors | Warranty | 50 years with normal use |

| Packing | 5.8m or 11.8m/length, 50-200m/roll, for DN20-110mm. | Quality | QA & QC system, Ensure traceability of each process |

| Application |

Drinking water, Fresh water, Drainage, Oil and Gas, Mining, Dredging, Marine, Irrigation, Industry, Chemical, Fire fighting... |

Service | R&D, production, sale and installation, after-sales service |

|

Matching products: Butt fusion, Socket fusion, Electrofusion, Drainage, Fabricated, Machined fitting, Compression fittings, Plastic Welding machines and tools, etc. |

|||

Welcome to visit our factory or conduct a third-party audit.

Welcome to contact us for products details and professional service.

Please send email to: chuangrong@cdchuangrong.com

Product Description

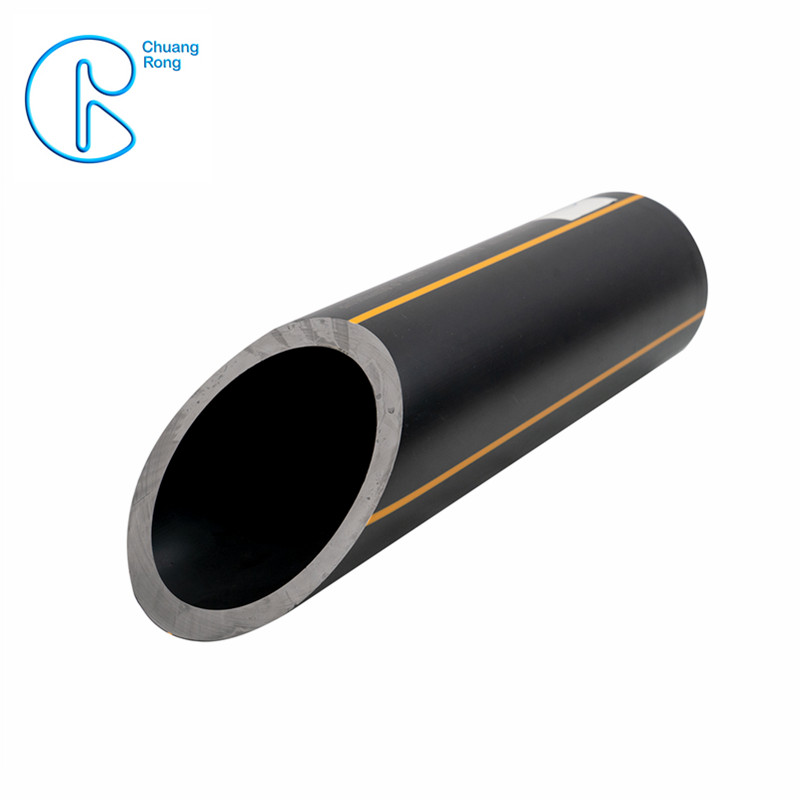

High Density Polyethylene (HDPE) piping systems are used all over the world for the supply and conveying of several kinds of media, including liquid, gas and powers as well as in mining and quarry applications.

High Density Polyethylene (HDPE) pipework systems have the main advantages over steel and ductile iron systems if lightness of weight and freedom from corrosion. The rapid growth in use of polyethylene is due in part to benefits over steel and iron systems, but possibly more to the development of several advanced and easy jointing techniques. Polyethylene has very good fatigue strength and special provision for surges frequently allowed when designing other thermoplastic pipework systems (as PVC) are not normally necessary.

High Density Polyethylene (HDPE) pipes are produced in size up to 2500mm in diameter, with nominal pressure rating PN4, PN6, PN10, up to PN25 (other pressure ratings also available). All pipes and fittings are manufactured in accordance with current EN12201, DIN 8074, ISO 4427/ 1167 and SASO Draft No.5208.

High Density Polyethylene (HDPE) piping system are used worldwide for conveying of water as well as for the transportation of hazardous fluids. It offers the following advantages to the customer:

Specification

| HDPE Pipe coil For Water Supply Or Irrigation | ||||||||||

| Nominal outside diameter Dn(mm) | PE80 Pipe | PE100 Pipe | ||||||||

| Nominal wall thickness en(mm) | ||||||||||

| PN4 | PN6 | PN8 | PN10 | PN12.5 | PN6 | PN8 | PN10 | PN12.5 | PN16 | |

| SDR33 | SDR21 | SDR17 | SDR13.6 | SDR11 | SDR26 | SDR21 | SDR17 | SDR13.6 | SDR11 | |

| 20 | - | - | - | - | 2.3 | - | - | - | - | 2.3 |

| 25 | - | - | - | 2.3 | 2.3 | - | - | - | 2.3 | 2.3 |

| 32 | - | - | 2.3 | 2.4 | 3.0 | - | - | 2.3 | 2.4 | 3.0 |

| 40 | - | 2.3 | 2.4 | 3.0 | 3.7 | - | 2.3 | 2.4 | 3.0 | 3.7 |

| 50 | 2.3 | 2.4 | 3.0 | 3.7 | 4.6 | 2.3 | 2.4 | 3.0 | 3.7 | 4.6 |

| 63 | 2.4 | 3.0 | 3.8 | 4.7 | 5.8 | 2.4 | 3.0 | 3.8 | 4.7 | 5.8 |

| 75 | 2.6 | 3.6 | 4.5 | 5.6 | 6.8 | 2.9 | 3.6 | 4.5 | 5.6 | 6.8 |

| 90 | 2.8 | 4.3 | 5.4 | 6.7 | 8.2 | 3.5 | 4.3 | 5.4 | 6.7 | 8.2 |

| 110 | 3.4 | 5.3 | 6.6 | 8.1 | 10.0 | 4.2 | 5.3 | 6.6 | 8.1 | 10.0 |

Material &Test

| SI NO. | PROPERTIES | UNIT | REQUIREMENT | Experimental parameters | Experimental Method |

| 1 | Density | Kg/m³ | More than 930(base resin) | 190℃,5KG | D method of GB/T1033-1986,experimental preparation is according to GB/T1845.1-1989 : 3.3.1 |

| 2 | Melt Flow Rate (MFR) | g/10min | 0.2-1.4,and the maximum deviation should not exceed the nominal value of the mix | 190℃,5kg | GB/T3682-2000 |

| 3 | Thermal stability (oxidation induction time) | min | More than 20 | 200℃ | GB/T17391-1998 |

| 4 | Volatile content | Mg/kg | Less than 350 | Appendix C | |

| 5 | Moisture content b | Mg/kg | Less than 300 | ASTMD4019:1994a | |

| 6 | Carbon black content c | % | 2.0-2.5 | GB/T13021-1991 | |

| 7 | Carbon black dispersion c | grade | Less than 3 | GB/T18251-2000 | |

| 8 | Pigment dispersion d | grade | Less than 3 | GB/T18251-2000 | |

| 9 | Resistant to gas components | h | More than 20 | 80℃,2Mpa(ring stress) | Appendix D |

|

Bear fast crack propagation (RCP) |

|||||

| 10 | Full size (FS) experiment :Dn ≥250mmor S4 experiment:pipe wall thickness ≥15mm | MpaMpa | Full size experiment’s critical pressure Pc.fs ≥ 1.5XMOP | 0℃0℃ | ISO13478:1997GB/T19280-2003 |

| 11 | Bear slow crack propagation (En≥5mm) | h | 165 | 80℃,0.8Mpa(experiment pressure) 80℃,0.92Mpa(experiment pressure) |

GB/T18476-2001 |

| a Non-black blends should meet the weatherability requirements in Table 6

b Water content is measured when the measured volatiles do not meet the requirements. When arbitration, the water content should be the measurement results as a basis for judging c Only apply to black mix d Only apply to non-black mix e If the S4 test results do not meet the requirements, you can follow the full-size experiment to re-experiment to full-size experimental results as the final basis. f PE80, SDR11 experimental parameters g PE100, SDR11 experimental parameters |

|||||

Workshop

CHUAGNRONG owns more 100 sets pipe production lines that are advanced at domestic and abroad,200 sets of fitting production equipment. The production capacity reaches more than 100 thousand tons. Its main contain 6 systems of water, gas, dredging, mining, irrigation and electricity, more than 20 series and more than 7000 specifications.

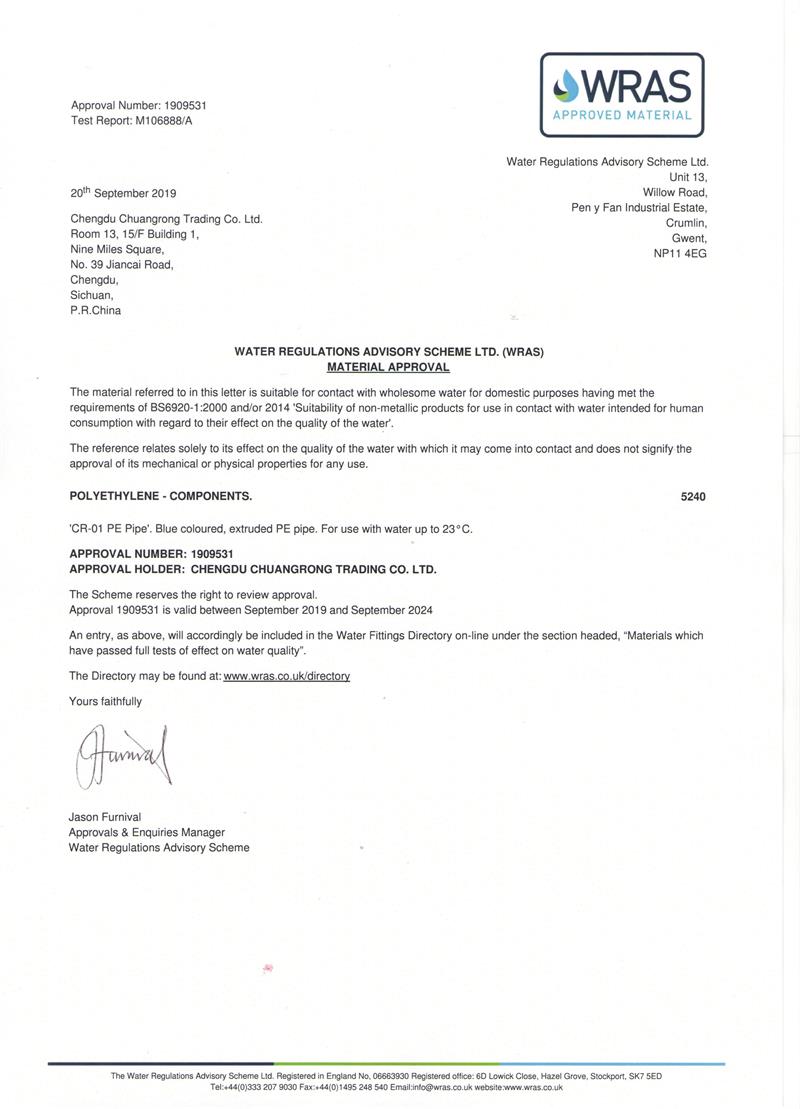

Certification

We can supply ISO9001-2015,WRAS, BV ,SGS, CE etc certification. All kinds of products are regularly conducted pressure-tight blasting test,longitudinal shrinkage rate test, quick stress crack resistance test, tensile test and melt index test, so as to ensure the quality of products totally reach the relevant standards from raw materials to finished products.

If you have any questions, you can feel free to contact us in anytime .

Welcome to contact us for products details and professional service.

Please send email to: chuangrong@cdchuangrong.com or Tel: + 86-28-84319855

Send your message to us:

Products categories

-

Phone

-

E-mail

-

Whatsapp

-

Skype

-

Top