Welcome To CHUANGRONG

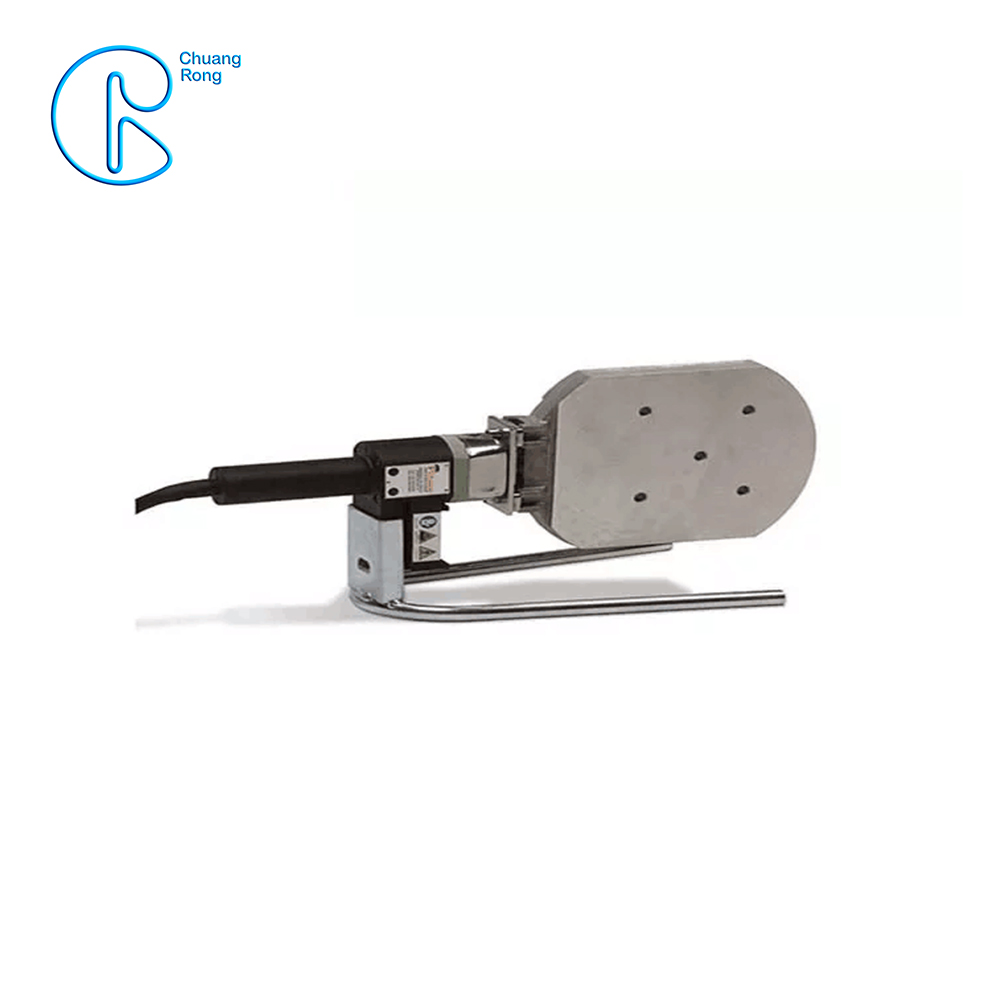

Hand Type 125 mm Socket Fusion Machine For PVC / PPR / HDPE Welding

Basic Information

| Usage: | Socket Pipe Welding | After-sales Service Provided: | Free Spare Parts, Field Installation, Commissioning And Training, Online Support, Video Technical Support |

|---|---|---|---|

| Working Range: | 75-125mm | Power Supply: | 220V/240V |

| Total Absorbed Power: | 800w | Materials: | HDPE,PP,PB,PVDF |

Product Description

Thank you for choosing a iweld product. The purpose of this manual is to describe the characteristics of the Socket fusion welding machine you have purchased and to provide instructions on how it is to be used.It contains all the information and precautions necessary for the machine to be used properly and safely by trained professionals. We recommend reading the manual thoroughly before attempting to use the machine.

The manual should be kept with the machine at all times for ease of consultation in the future by youor by other users. We are confident that you will be able to become thoroughly familiarwith the machine and that you will be able to use it for a long period with complete satisfaction.

STANDARD COMPOSITION

-Soktet welder

-Fork support

-Bench vice

-Allen wrench

-Pin for sokets&spigots

-Carrying case

|

Model

|

R125

|

|

Materials

|

PE/PP/PB/PVDF

|

|

Working range

|

20-125MM

|

|

Weight

|

9.0KG

|

|

Rated voltage

|

220VAC-50/60Hz

|

|

Rated power

|

800W

|

|

Pressure range

|

0-150bar

|

|

Protection level

|

P54

|

R25, R63, R125Q socket fusion welding machines are items of manual equipment with contact heating element used for melting plastic in the welding of pipe or connector sockets.

TE series Socket fusion welding machines allow the temperature to be varied.

They all are suited to weld polyethilene (PE), polypropylene (PP;PP-R)and polyvinyl di-fluoride (PVDF) components.

Send your message to us:

Products categories

-

Phone

-

E-mail

-

Whatsapp

-

Skype

-

Top