Welcome To CHUANGRONG

PVDF 、PP 、PE 、PFA Pipe Fully Automatic Infrared Butt fusion Welding Machine

Product Description

◆ Automatic program control

◆ Standard parameter mode

◆ Custom parameter mode is suitable for manufacturers of different brands to input specific welding parame- ters.

◆ Temperature range 0-600℃

◆ Printable welding parameters

◆ Quick installation self-locking clamp

◆ Magnetic clamp for easy replacement

◆ Humanized design makes operation easier

◆ Software can be upgraded remotely

Product Description

● Specialized for fusion joint of Ultra-Pure water pipeline used for semiconductor manufacturing process.

● For fusion of the high-end polymer material pipeline systems :ultra-pure chemicals ,medical, laboratory .biopharmaceutical .etc.

● Infrared non-contact radiation heat exchange fusion welding tech- nologies for pipes made of materials such as PVDF,PP, PFA etc.

● Suitable for butt welding of straight pipes, pipes with fittings, and fittings with fittings.

Specification

| Model | IR-110 CNC | IR-250 CNC |

| Working range 【mm】 | 20-110mm | 110-250mm |

| Weldable materials | PFA 、PP 、PE 、PVDF | |

| Power requirements | 220VAG 50/60Hz | |

| Max power 【W】 | 2050 | 8000 |

| Heating plate power【W】 | 1200 | 6800 |

| Milling cutter power 【W】 | 850 | 1200 |

| Rack size(WXDXH) | 525*670*410mm | 1200* |

| Machine weight 【kg】 | 120 | 320 |

| Heating plate temperature range | 180-600℃ | 180-550℃ |

| IP level | 65 | 65 |

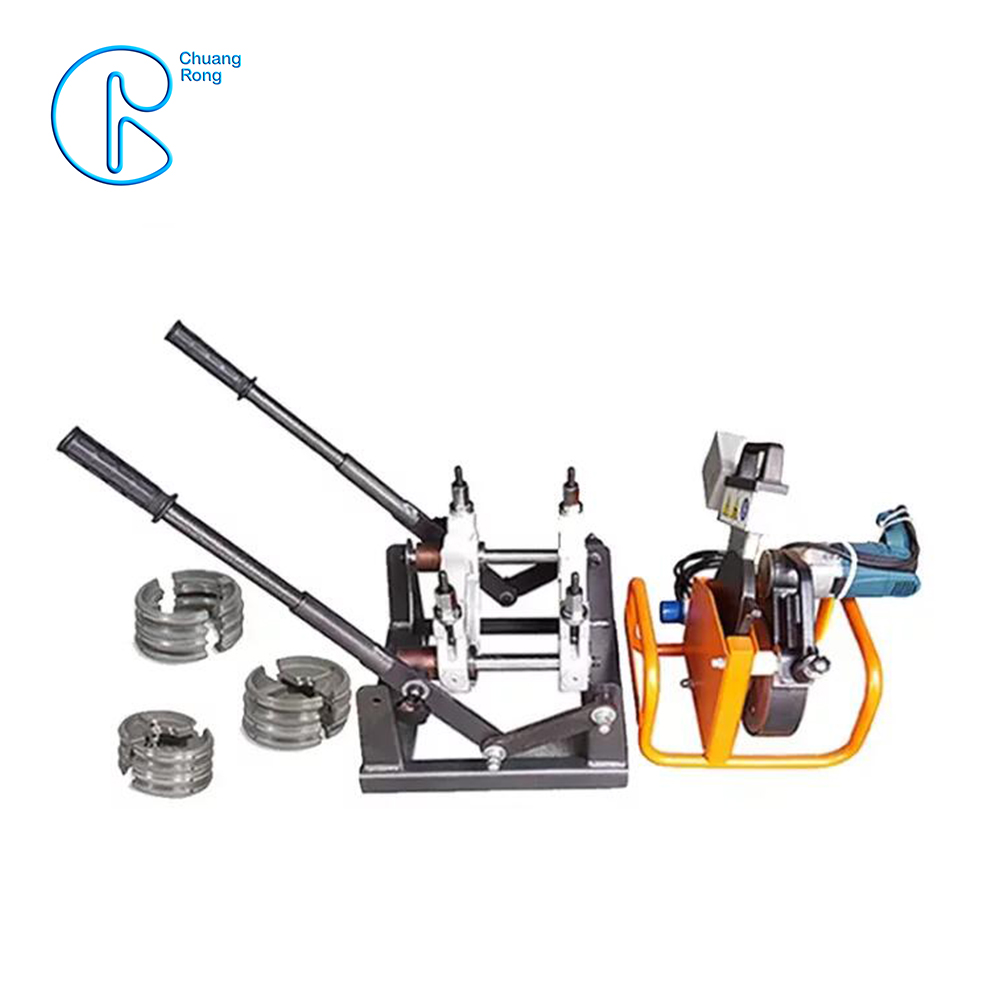

Standard configuration:

◆ Machine Body/Tool Box Stand

◆ Infrared heat plate

◆ Milling cutter

◆ 110 clamp

◆ Magnetic inner clamp 20-90mm

◆ Printer

On request :

◇ Inch clamp

◇ Extension tool board

Features

1. Touch screen operation, automatic import after parameter selection, humanized operation pro- cess design, you can operate according to the screen prompts, easy for beginners to operate.

2. Principle of infrared thermal radiation heating.

3. Four sets of high-precision pipe clamps, 2 sets each for wide and narrow, to facilitate fixing short- sized elbows and flanges.

4. Servo drive principle, size positioning preparation, and accurate pressure control.

5. The clamp structure can be quickly locked for easy operation and improved welding efficiency.

6. The centering adjustable structure can be adjusted up and down, front and back, to facilitate the centering of pipes and fittings.

7. The stainless steel outer protective cover of the heat plate is designed to prevent accidental burns to the operator.

8. Some standard welding parameters are prefabricated to facilitate operator selection.

9. Reserve a custom window to facilitate enterprises to import parameters suitable for their own ma- terial welding.

10. Ergonomic design makes it convenient for the operator to operate the welding machine while standing.

11. The milling cutter limit design reserves a standard pipe length for welding to facilitate welding operations.

12. Prefabricated non-adhesive label printer for easy printing of welding reports.

13. The automatic retractable heat plate mechanism reduces the delay in removing the hot plate caused by human factors.

14. The temperature control range is large 180-600℃.

15. Can weld pipes made of PPH/PVDF/PFA/PE/PPN/ECTFE and oth- er materials.

If you have any questions, you can feel free to contact us in anytime .

Welcome to contact us for products details and professional service.

Please send email to: chuangrong@cdchuangrong.com or Tel: + 86-28-84319855

Send your message to us:

Products categories

-

Phone

-

E-mail

-

Whatsapp

-

Skype

-

Top