Welcome To CHUANGRONG

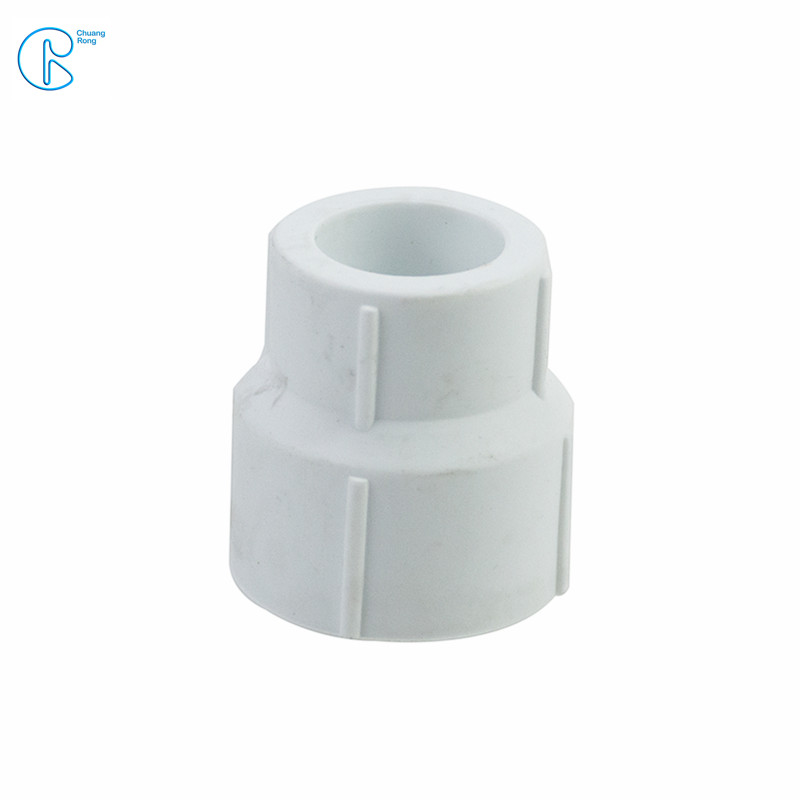

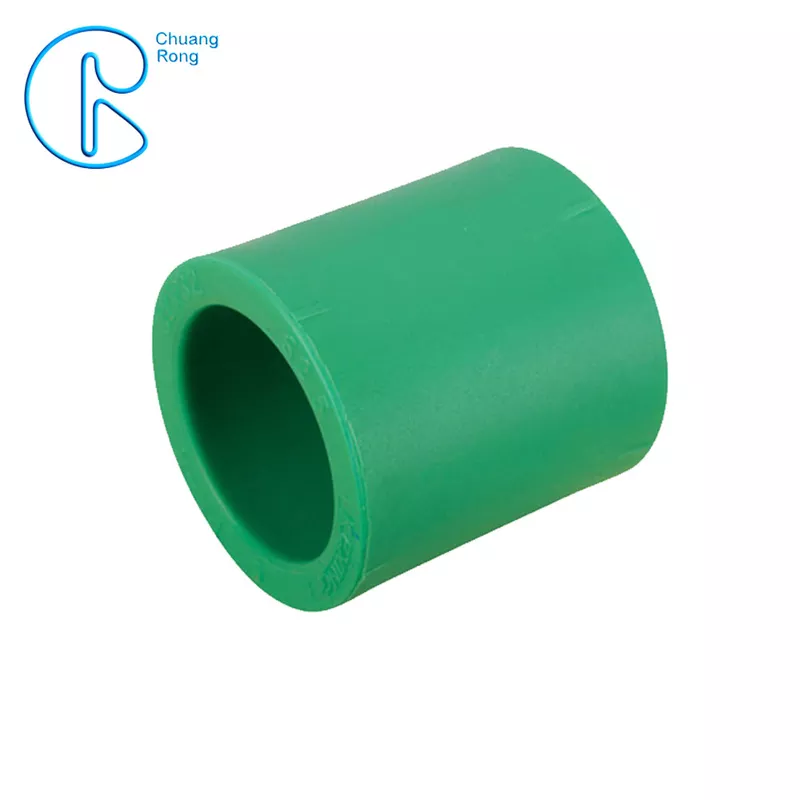

Green PPR Reducer In Pressure 25 For Heating / Air Conditioning System

Detail Information

| Product Name: | PPR Reducer | Shape: | Reducer |

|---|---|---|---|

| Head Code: | Round | Color: | Green |

| Brand: | CR | Production Temperature: | -40 – +95°C |

Product Description

Green PPR Reducer In Pressure 25 For Heating / Air Conditioning System

Realize the connection between pipes or fittings of different diameters, socket welder connection, convenient and simple, safe and environmentally friendly

|

Physical Properties |

Typical Value* |

Unit |

TestMethod |

|

|

Density |

905 |

kg/m3 |

ISO 1183 |

|

|

Melt Flow Rate |

(230℃/2.16kg) |

0.25 |

g/10 min |

ISO 1133 |

|

Tensile Stress at Yield |

(50 mm/min) |

25 |

MPa |

ISO 527-2 |

|

Tensile Strain at Yield |

(50 mm/min) |

10 |

% |

ISO 527-2 |

|

Modulus of Elasticity in Tension |

(1 mm/min) |

900 |

MPa |

ISO527 |

|

Charpy Impact Strength,notched |

(+23℃) |

40 |

kJ/m2 |

ISO 179/1eA |

|

Charpy Impact Strength,notched |

(0℃) |

4 |

kJ/m2 |

ISO 179/1eA |

|

Charpy Impact Strength, notched |

(-20℃) |

2 |

kJ/m2 |

ISO 179/1eA |

|

Mean Linear Thermal Coefficient of Expansion from 0°C to 70℃ |

1.5 |

*10-4K-1 |

DIN 53752 |

|

|

Thermal Conductivity |

0.24 |

WK-1m-1 |

DIN 52612 Part 1 |

|

Specificaion

|

Descrlption |

d |

d1 |

D |

D1 |

L |

|

dn25x20 |

20 |

20 |

34 |

28 |

37 |

|

an32x20 |

32 |

20 |

43 |

28 |

41 |

|

d032x20 |

32 |

20 |

43 |

34 |

53 |

|

dn40x20 |

40 |

20 |

53 |

28 |

48 |

|

dn40x20 |

40 |

20 |

53 |

34 |

48 |

|

dn40x32 |

40 |

32 |

53 |

43 |

63 |

|

dn50x20 |

50 |

20 |

67 |

28 |

56 |

|

dn50x20 |

50 |

20 |

67 |

34 |

54 |

|

an50x32 |

50 |

02 |

67 |

43 |

54 |

|

dn50x40 |

50 |

40 |

67 |

43 |

54 |

|

dn63x20 |

63 |

20 |

84 |

28 |

68 |

|

dn63x20 |

63 |

20 |

84 |

34 |

66 |

|

dn63x32 |

63 |

32 |

84 |

43 |

66 |

|

dn63x40 |

63 |

40 |

84 |

53 |

66 |

|

dn63x50 |

63 |

50 |

84 |

67 |

66 |

|

dn75x40 |

75 |

40 |

100 |

53 |

68 |

|

dn75x50 |

75 |

50 |

100 |

67 |

74 |

|

dn75x63 |

75 |

63 |

100 |

84 |

70 |

|

dn90x63 |

90 |

63 |

120 |

84 |

82 |

|

dn90x75 |

90 |

75 |

120 |

100 |

83 |

|

dn110x63 |

110 |

63 |

148 |

84 |

88 |

|

dn110x75 |

110 |

75 |

148 |

100 |

98 |

|

dn110x90 |

110 |

90 |

148 |

120 |

95 |

|

dn125x110 |

125 |

110 |

150 |

141 |

100 |

|

dn160x125 |

180 |

125 |

204 |

150 |

110 |

Advantage

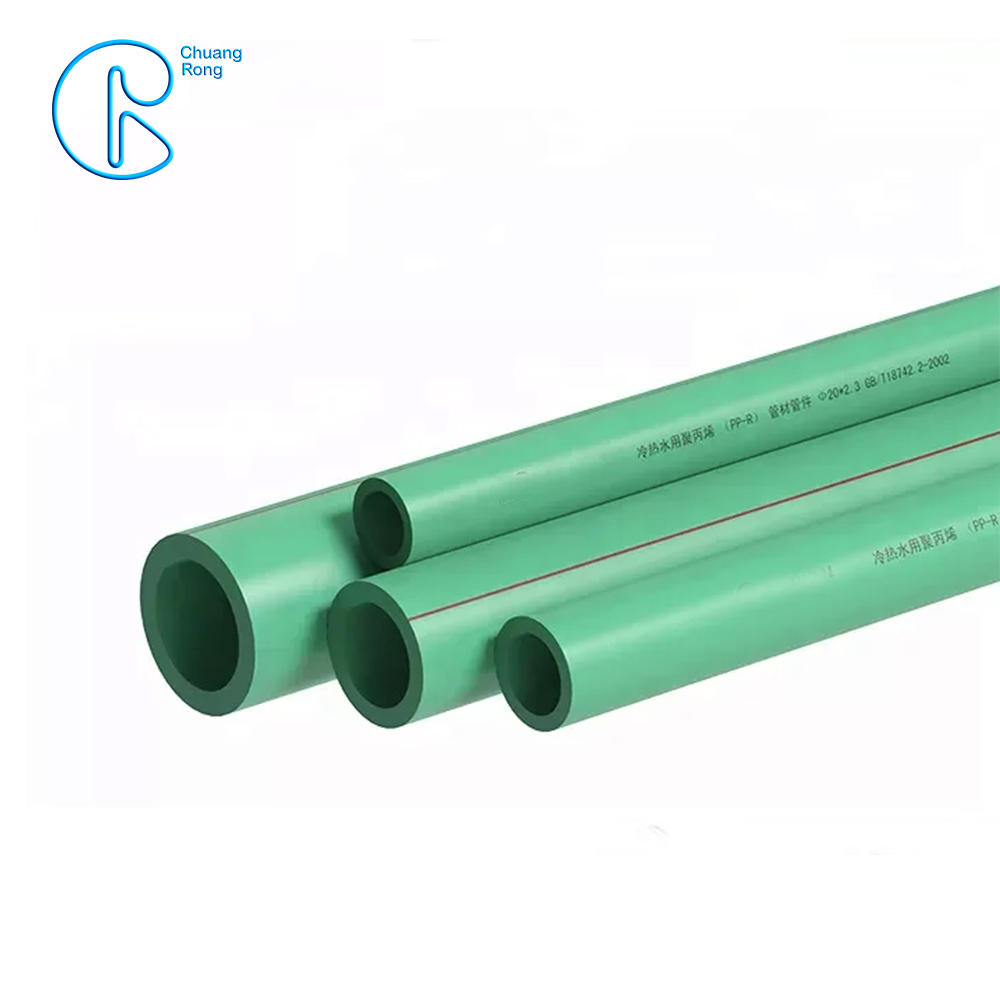

Perfect Thermal Fusion Joints: The unique socket-fusion welding technique creates a monolithic, leak-proof joint that is as strong as the pipe itself, ensuring ultimate system integrity.

Exceptional Heat Resistance: Ideal for hot and cold water applications. capable of withstanding continuous operating temperatures up to 70℃ and higher short-term temperatures.

Superb Hygiene and Water Purity: Inert material prevents corrosion and scaling, ensuring no taste, odor, or contamination of potable water, and maintaining high water quality.

Long Service Life & Durability: Excellent resistance to chemical andelectrochemical corrosion guarantees a service life of over 50 vears under normal operating conditions.

Energy Efficient and Insulating; Low thermal conductivity minimizes heat loss in hot water lines, saving energy, and prevents surface condensation in cold water lines.

Light weight and Easy Installation: Significantly lighter than metal pioes. making transportation and installation faster,easrer,and more cost-effective.

Application

CHUANGRONG has an excellent staff team with rich experience. Its principal is Integrity, Professional and Efficient. It has established business relationship with more than 80 countries and zones in relative industry. Such as United States, Chile, Guyana, The United Arab Emirates, Saudi Arabia, Indonesia, Malaysia,Bangladesh, Mongolia, Russia, Africa and so on.

Welcome to contact us for products details and professional service.

Please send email to: chuangrong@cdchuangrong.com or Tel: + 86-28-84319855

Send your message to us:

Products categories

-

Phone

-

E-mail

-

Whatsapp

-

Skype

-

Top