Welcome To CHUANGRONG

Top Quality Cantilever Type Automatic Pipe Welding Machine

Our well-equipped facilities and exceptional excellent control throughout all stages of manufacturing enables us to guarantee total buyer gratification for Top Quality Cantilever Type Automatic Pipe Welding Machine, We believe that this sets us apart from the competition and makes shoppers choose and trust us. We all wish to make win-win deals with our buyers, so give us a contact today and create a new pal!

Our well-equipped facilities and exceptional excellent control throughout all stages of manufacturing enables us to guarantee total buyer gratification for China Pipe Welding Machine and Orbit Welding Machine, Now we have won a good reputation among overseas and domestic clients. Adhering to the management tenet of “credit oriented, customer first, high efficiency and mature services”, we warmly welcome friends from all walks of life to cooperate with us.

Basic Information

Standard composition

1.Machine body

2.Milling cutter

3.Heating plate

4.Hydraulic control unit

5.Support

6.Clamps

| Product Name: | Automatic Welding Machine | Working Range: | 160-355/250-400/315-500/400-630MM |

|---|---|---|---|

| Usage: | Pipe Fittings Welding | Warranty: | 1 Year |

| Single Phase: | 50/60Hz | Protection Level: | IP54 |

Product Description

Application

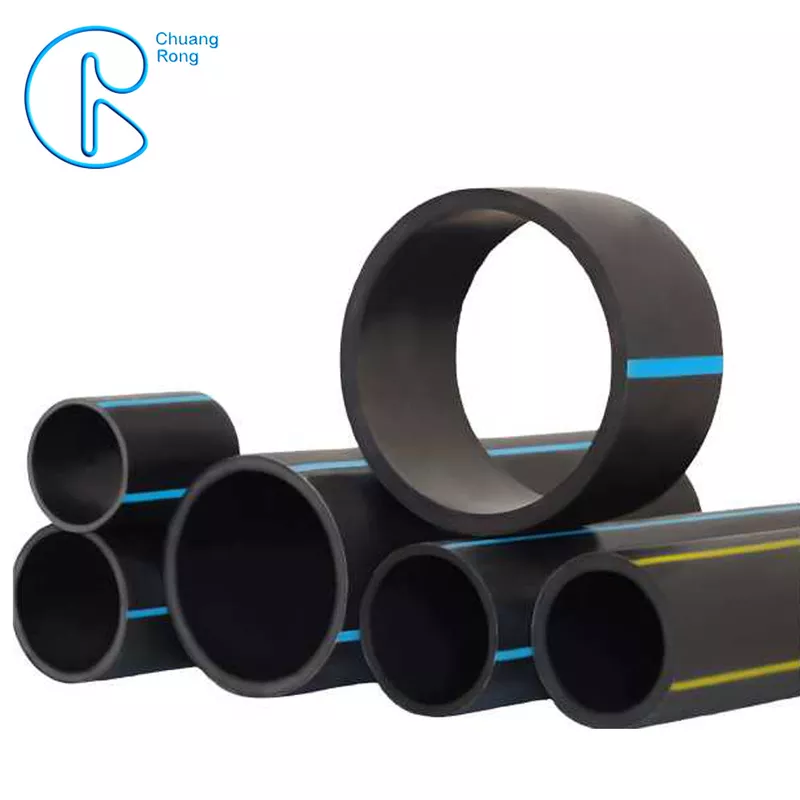

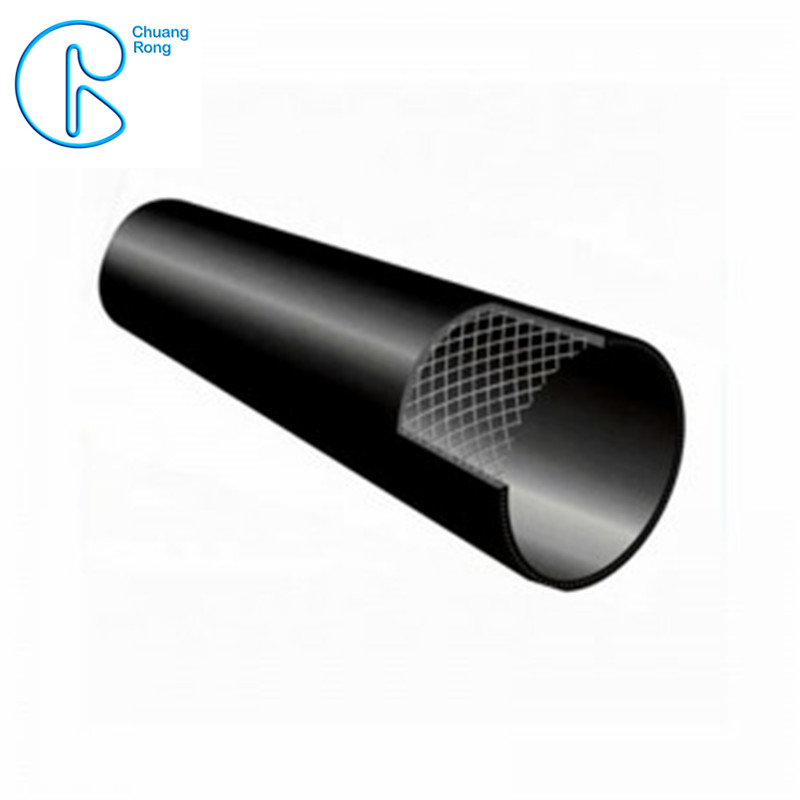

CNC is an on-site butt welding machine for pipes and fittings in Polyethylene (PE), Polypropylene (PP), and other thermoplastic materials intended for the transport of water under high pressure.

We remind you that the use of such machines is limited to authorized skilled and certified personnel, in accordance with the Legislation and Regulations in force.

Viewing and downloading

Click the Data Query button to enter the welding data management screen.

Features

| GENERAL | 160 | 250 | 315 |

| Working range: | Ø 63 ÷ Ø 160 mm | Ø 75 ÷ Ø 250 mm | Ø 90 ÷ Ø 315 mm |

| Materials: |

HDPE, PB, PP, PVDF |

||

| Range of ambient temperatures: |

-10 ÷ +40 °C |

||

| Power supply: |

230 VAC 50-60 Hz |

||

| Nominal power | 2600 W | 3950 W | 4950 W |

| Pressure’s working range: |

Up to150 bar |

||

| Weight | 80 Kg | 144 Kg | 194Kg |

| Welding cycle |

Automatic |

||

| Memory capacity |

4000 stored weldings |

||

| Transfer of stored data |

pdf document on USB flash drive |

||

| Barcode traceability | Pipe/Fitting upon ISO 12176-4Operator upon ISO 12176-3 | ||

| GPS |

Enabled |

||

| Noise (dBA) |

LpA = 74 dBA |

||

| Chassis | 160 | 250 | 315 |

| Overall thrust section: | 9.42 | 10.99 cm2 | 12.56 cm2 |

| Dimensions: [ W×D×H ] | 600x400x410 [mm] | 960x650x950 [mm] | 1090 x 800 x 1100 [mm] |

| Weight: | 35 Kg | 66 Kg | 150 Kg |

| Facer | 160 | 250 | 315 |

| Nominal power | 800 W | 900 W | 900W |

| Dimensions: [ W×D×H ] | 430×330×80 [mm] | 440×450×380 [mm] | 600×460×390 [mm] |

| Weight: | 7.5 Kg | 15 Kg | 21 Kg |

| Heater | 160 | 250 | 315 |

| Nominal power | 1000W | 2000W | 3000W |

| Dimensions: [ W×D×H ] | 350×50×450 [mm] | 470×50×490 [mm] | 470×50×600 [mm] |

| Weight: | 3.6 Kg | 8 Kg | 13 Kg |

| Facer/heater holder | 160 | 250 | 315 |

| Dimensions: [ W×D×H ] | 300×370×440 [mm] | 380×265×600 [mm] | 590×315×650 [mm] |

| Weight: | 3.5 Kg | 10 Kg | 16 Kg |

| Hydraulic gearcase | |||

| Nominal power |

1100 W |

||

| Pressure range: |

up to 150 bar |

||

| Hydraulic oil: | Viscosity class 46 o 68 ISO 3448Recommended :- TEXACO RANDO HDZ 46- ESSO UNIVIS N 46- SHELL TELLUS T 46 | ||

| INSERT DIAMETER (welght [kg] full set) | 160 | 250 | 315 |

| Ø 63mm | 2.6 | 8.4 | |

| Ø 90 mm | 2.3 | 8.0 | 16.0 |

| Ø 110 mm | 2.1 | 7.5 | 15.5 |

| Ø 160 mm | 6.0 | 14.0 | |

| Ø 200 mm | 4.8 | 12.5 | |

| Ø 250 mm | 10.5 | ||

| On request | Ø 75/125/140mm | Ø 75/125/140/180/225mm | Ø 125/140/180/225/280mm |

SAFETY CRITERIA

The use of the of this product is intended exclusively to qualified personnel according to the standards in force.

Use the machine only for purposes as described on “Fields of Application” and according to the operator’s manual. Any other use is forbidden, since it may cause harm to persons, damage the machine or other objects.

Do not remove the safety devices (switches, micro-switches, seals, etc).

Replace defective or worn out parts only with Original spare parts.

Any intervention or repair on the machine has to be performed by qualified personnel.Our well-equipped facilities and exceptional excellent control throughout all stages of manufacturing enables us to guarantee total buyer gratification for Top Quality Cantilever Type Automatic Pipe Welding Machine, We believe that this sets us apart from the competition and makes shoppers choose and trust us. We all wish to make win-win deals with our buyers, so give us a contact today and create a new pal!

Top Quality China Pipe Welding Machine and Orbit Welding Machine, Now we have won a good reputation among overseas and domestic clients. Adhering to the management tenet of “credit oriented, customer first, high efficiency and mature services”, we warmly welcome friends from all walks of life to cooperate with us.

Send your message to us:

Products categories

-

Phone

-

E-mail

-

Whatsapp

-

Skype

-

Top